-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New BS-0 "dropped" before delivery, what would you do?

- Thread starter WobblyHand

- Start date

- Joined

- Dec 18, 2019

- Messages

- 6,447

It's not the nick, it's more the bearings or the gears that I was concerned about. I have it partially apart, and have removed the worm, By eye it's fine. I will look at it under a microscope for any evidence of a hit. There were 2 long thin pieces of swarf on the worm. They looked like remnants of machining, as compared to damage. The BS-0 turned ok, and it wasn't hard to adjust the backlash to zero. Still thrashing a little bit to remove the backing plate of the chuck. Doesn't want to come off just yet. Then I can remove the spindle and inspect the gears. Yes my BS-0 is full of grit, been cleaning it as I go. Thinking it probably is ok, but only way to know is to fully remove the spindle.As for the box and packing, who cares, your throwing it in the trash anyhow. Its whats inside that matters.

For that nick on the screw, it looks like a standard socket head cap screw, If the nick bothers you it is about $0.50 at the hardware store.

OK that's the easy parts.

with not knowing just how much of an impact the end of the shaft took, my first concern would be the bearings, It does not take a lot of impact to damage bearings. You get what I have always called Brinell marks, it is where the force presses the balls or rollers into the races and leaves very tiny dents. In time these tiny dents will become big dents and a very rough bearing. The only way to inspect is to take the bearing out, clean all of the grease out of it and look at the races with a magnifying glass for shiny spots spaced the same as the balls or rollers, if it is really bad you can feel the dents as you rotate the bearing in your fingers while applying an axial load.

In this case the shaft will never be turning at high RPM, (unless you have a really strong fast arm). this tool in the grand scheme of things gets very little actual use and the bearing are so over rated for the application it is ridiculous, The bearings were chosen for their physical size and not for their load carrying ability or RPM handling ability. This is a common engineering compromise.

Unless the casting broke the gears should be fine.

From what I can see in the pics, it does not look like the shaft took a real hard hit, the damage to the head of that screw is not much, so I would be real surprised at any casting damage. Worst case (while still unlikely) would be to the bearings on that shaft. If the bearings look and feel good grease them back up, put it back together, and be confident that what they shipped is what you got.

While you have it apart you can clean it all out, Many clone machines are known to have a lot of swarf from manufacturing still floating around inside and the grease used is of questionable quality.

- Joined

- Dec 18, 2019

- Messages

- 6,447

No near by warehouses around me to swap things out. Maybe a 2 or 3 day drive away. I don't really think it's broken, but I'm not yet sure it's undamaged. So I'll try pulling the spindle to look at the bearings. I will look at them under a microscope. If they are good, I'm fine. If damaged, I'll be looking for a refund, or another "good" BS-0 unit.I feel your pain. I went through almost exactly the same thing with a Chinese co. on eBay. I tried to work with them and in hindsight I should have probably bailed early on. Mine was a tool grinder clone with even less styrofoam. The thing weighs 110lb and turned the bottom of the packing to dust and was not the machine promised and had damage. I also got if I tried to return it through the mail it would get further damaged. They had warehouses in SF and LA where they had the correct machine so I drove the 7hr round trip to swap it out. All day sucker. This was with much back and forth, and don’t worry, but so much misunderstanding and messing about. When all said and done it was over an 8wk period. I ended up ok but it was a LOT of work.

- Joined

- Feb 17, 2013

- Messages

- 4,406

I've had a small amount of experience with reluctant Chinese vendors. Some of them REALLY don't want to send out a refund, or have to deal with a return. They'll try to send you jumping through hoop after hoop after hoop, hoping to wear you down.

I agree with what @mickri said ... there's really no way to find possible (probable) internal damage without a complete tear-down. NOT your job! What I would do if I were in your shoes would be to (1) send them your photos, in case you haven't already done so, then (2) let them know that you want a full refund without further delay, and (3) let them know that if they won't give you the refund, then you'll go through your credit card company (or PayPal, whichever you used). And if they do want the item returned, be cooperative, but be sure it's NOT at your expense.

I agree with what @mickri said ... there's really no way to find possible (probable) internal damage without a complete tear-down. NOT your job! What I would do if I were in your shoes would be to (1) send them your photos, in case you haven't already done so, then (2) let them know that you want a full refund without further delay, and (3) let them know that if they won't give you the refund, then you'll go through your credit card company (or PayPal, whichever you used). And if they do want the item returned, be cooperative, but be sure it's NOT at your expense.

- Joined

- Dec 18, 2019

- Messages

- 6,447

Well too late for that... Where were you this morning? Just kidding. I've removed the worm, since it was easy. Pulled the chuck off, but not the back plate. Cleaned out a lot of internal swarf and grinding grit. Given that, you are saying I'm stuck? How can one tell if damaged if not inspected? Isn't that a Catch 22?

- Joined

- Dec 18, 2019

- Messages

- 6,447

Well, it's further apart. Figured I have little to lose, if nothing else, it could be practice. Finally removed the back plate. This thing won't win many quality awards, but so far is functional, but has a couple of questionable machining moves. Pin hole in the ground surface of the casting - it's cosmetic. Brass gibs are well, just not well made, and appear to be redone with the same piece. Counter bore done with a normal drill followed up with plated pan head like screws. I didn't bother taking a picture of the back plate, but it's not finely machined. We'll see about concentricity. Miserable grey grit everywhere. What's left is to remove the circular nut so I can pull the spindle out. It's time to stop for now. Been at it a while. Tomorrow, I'll check in the garage if I have a pin spanner. If not, I'll have to make something. Looks like the holes are 4mm, but I need to measure them.

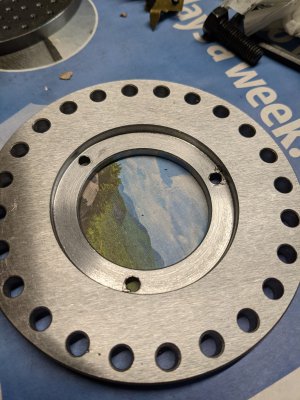

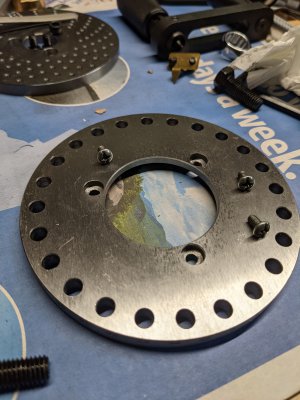

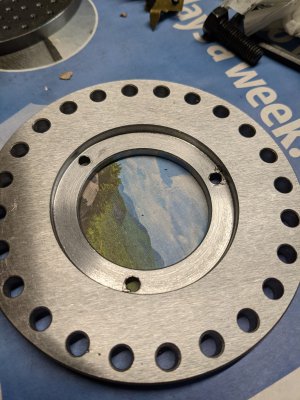

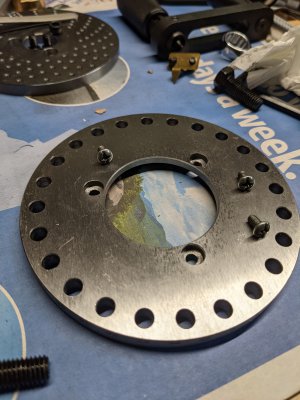

Pinhole. -----------------------------------------------------------------Brass gib ---------------------------------------Back of degree plate, swarf on mating surface

Front of degree plate, drilled CB.------------------------- Round nut to be removed.

All the videos are right, it's kind of a kit. Hope the bearings are ok. Without the worm in place, it's kind of hard to rotate the spindle - meaning its very tight. With the worm it rotates ok, although maybe not as smooth as I'd like.

Pinhole. -----------------------------------------------------------------Brass gib ---------------------------------------Back of degree plate, swarf on mating surface

Front of degree plate, drilled CB.------------------------- Round nut to be removed.

All the videos are right, it's kind of a kit. Hope the bearings are ok. Without the worm in place, it's kind of hard to rotate the spindle - meaning its very tight. With the worm it rotates ok, although maybe not as smooth as I'd like.

- Joined

- Nov 14, 2016

- Messages

- 3,001