Just noticed that you are brand new to the forum. Welcome aboard. Lots of knowledgeable people on here who will help you out.

Thanks! I have lurked on here for a while as I get my head around taking up machining as a hobby to compliment my other... umm.. hobbies

bigger lathe + tailstock removed + military cot clamped to ways = guest bedroom!

Ha, sounds like I need a few cranes to get that lathe into the room

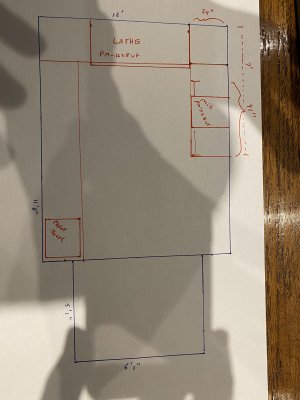

My bedroom shop is 15 x 12. No matter what the room size is, it is too small.

Robert

I agree but living in the city constrains my space. I will be happy to have a bit more space and a real two car garage (20x22).