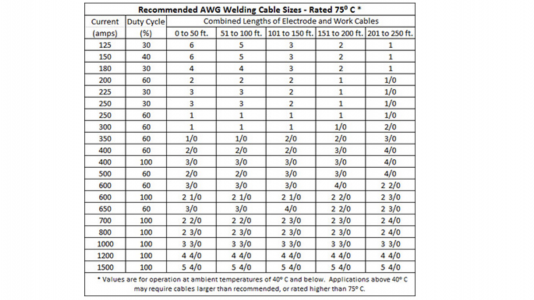

Just to be clear, I have a older Miller Dialarc HF, which goes up to 310 amps.I have the same machine, a 220V, 210A max Miller Thunderbolt 210. They do come with #4 cables. The #4 cables are just big enough to do the job.

My other “stick welder” (a Miller Dynasty 210DX) has much thicker cables (2/0). I cannot tell the difference when welding with either #4 or 0/2 cables.

On another post , the majority suggested #1 is

adequate.

At 210 amps, why would you have 2/0 leads ?

I am concerned that my old taped up leads might be 3/0 or even 4/0. I have no way to tell, no visible labels. It welds great at 200 amps and higher, I don’t want to have any problems.