- Joined

- Dec 26, 2016

- Messages

- 2,018

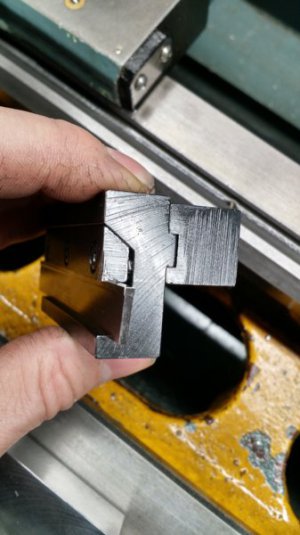

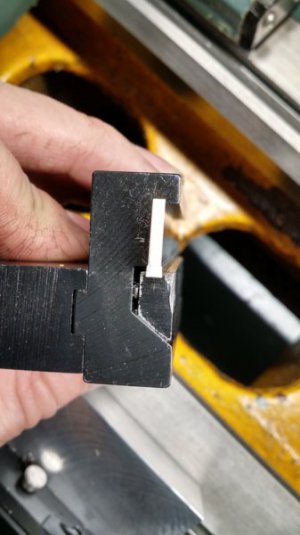

I have an OXA qc tool post and would really like to make a holder for it that can hold a parting blade upside down and centered, I tried to use the parting holder that came with the set by just flipping the blade (what can I say, I'm a rookie) but it soon became evident that centering the blade was impossible with that holder.

I need to machine a new holder that

A= fits in another( i.e. facing/turning )holder but holds the parting blade inverted.

B= a totally new holder that fits the tool post .

C= any other designs that basically does the same thing like parting from the opposite side of the spindle,etc.

No matter what holder I make it still has to be adjustable so I could center the blade.

All this idea came about after Mikey in this thread suggested to make a holder specifically for an inverted parting blade, I'd like to know if anyone has ever machined a holder for this purpose or if you have any ideas ,designs,comments.

I need to machine a new holder that

A= fits in another( i.e. facing/turning )holder but holds the parting blade inverted.

B= a totally new holder that fits the tool post .

C= any other designs that basically does the same thing like parting from the opposite side of the spindle,etc.

No matter what holder I make it still has to be adjustable so I could center the blade.

All this idea came about after Mikey in this thread suggested to make a holder specifically for an inverted parting blade, I'd like to know if anyone has ever machined a holder for this purpose or if you have any ideas ,designs,comments.