- Joined

- Mar 10, 2012

- Messages

- 1,368

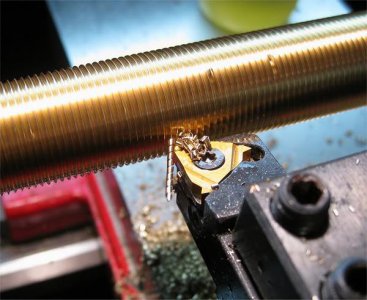

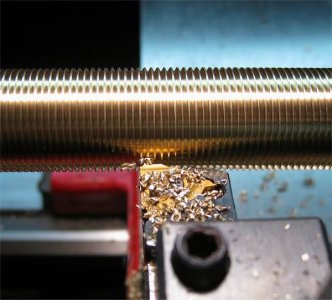

I tried grinding my own HSS tools and found my skill very lacking. I went to a tangential tool holder (the Diamond Tool holder, actually) and I think it's the easiest way for newbies to get up and running. I was going to go with the Warner HSS inserts but the thought of having only one source for the HSS inserts quickly changed my mind. With the tangential holders you use a square 1/4" HSS tool that is reground on one surface (2 for threading). You can find good HSS blanks easily from many sources. Yes, you should at least attempt to learn about the various angles and reliefs needed and why for lathe tool bits but if you're like me and would like to get to regular turning, facing, etc... and learn to grind in the off time then go with the tangential holder.