-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Need a super-sized micrometer

- Thread starter pbiYoung

- Start date

- Joined

- Mar 26, 2018

- Messages

- 2,724

What’s the material and what measurement tolerance? There are ultrasonic thickness measuring instruments for sheet and film applications like this.

Example: Mxmoonfree Ultrasonic Thickness Gauge Meter 0.8-350mm/0.03-13.77" | 0.01mm/0.001" Thickness Measuring Tools with QC Mode, Data Recording, Auto Calibration, NDT for Metals, Glass, Ceramics, Plastics https://a.co/d/2h1DoUp

Example: Mxmoonfree Ultrasonic Thickness Gauge Meter 0.8-350mm/0.03-13.77" | 0.01mm/0.001" Thickness Measuring Tools with QC Mode, Data Recording, Auto Calibration, NDT for Metals, Glass, Ceramics, Plastics https://a.co/d/2h1DoUp

- Joined

- Jan 25, 2015

- Messages

- 2,558

Yep, I have an ultrasonic thickness measuring tool.

I use it to measure the thickness of piston crowns when I need to fly cut valve reliefs into them and also when reworking the squish areas.

you could also use something like this with a 1-2-3 block:

www.starrett.com

www.starrett.com

someone out there might also make a 1” mic with a deep throat, but I’ve never seen one. But that doesn’t mean there isn’t one out there…

I use it to measure the thickness of piston crowns when I need to fly cut valve reliefs into them and also when reworking the squish areas.

you could also use something like this with a 1-2-3 block:

224ARLZ Interchangeable Anvil Micrometer Set

The Starrett 224, 224M Series Interchangeable Anvil Micrometers feature a wide range of measurement and flexibility. Each micrometer is equipped with a series of easily interchangeable anvils, thus providing the full range in steps of 1" or 25mm with a single micrometer. This model features 2-6"...

someone out there might also make a 1” mic with a deep throat, but I’ve never seen one. But that doesn’t mean there isn’t one out there…

- Joined

- Feb 1, 2015

- Messages

- 9,616

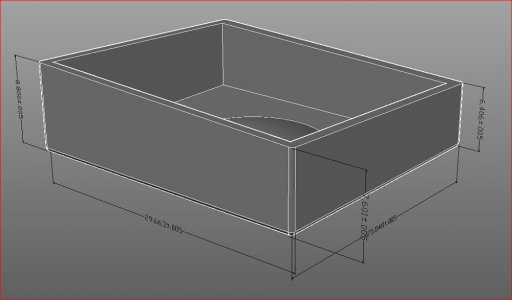

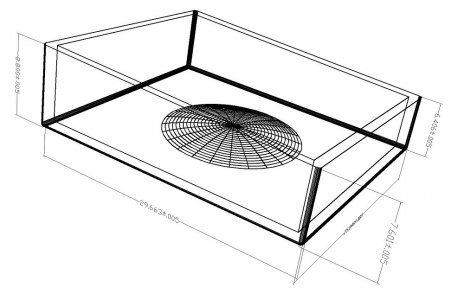

Is the thickness uniform? On a mill with a Quill DRO, I would mount a dial test indicator in the spindle and lower it to zero out on the table and zero the DRO, Then I would place the box on the table and lower the quill to zero the dial test indicator and read my thickness on the DRO. You should be able to get within a thou of the actual thickness.

The gotcha is that the bottom of the box has to be flat or at least the point of contact of the test indicator probe has to be in contact with the table so yo may have to press down in that area to establish contact.

The gotcha is that the bottom of the box has to be flat or at least the point of contact of the test indicator probe has to be in contact with the table so yo may have to press down in that area to establish contact.

- Joined

- Mar 14, 2022

- Messages

- 696

If you have a vertical mill this would work. Use a .0005" test indicator set up in the mill's tool holder. Zero the indicator on the table, raise the tool holder, mount the box and zero the indicator on the box's bottom. Depending on the condition of your equipment you should be accurate to +/-.0025".Mill table?

Same as RJ posted.

That is a good solution if an ultrasonic thickness measuring instrument is available. What might be another method ?What’s the material and what measurement tolerance? There are ultrasonic thickness measuring instruments for sheet and film applications like this.

Example: Mxmoonfree Ultrasonic Thickness Gauge Meter 0.8-350mm/0.03-13.77" | 0.01mm/0.001" Thickness Measuring Tools with QC Mode, Data Recording, Auto Calibration, NDT for Metals, Glass, Ceramics, Plastics https://a.co/d/2h1DoUp

What’s the material and what measurement tolerance? There are ultrasonic thickness measuring instruments for sheet and film applications like this.

Example: Mxmoonfree Ultrasonic Thickness Gauge Meter 0.8-350mm/0.03-13.77" | 0.01mm/0.001" Thickness Measuring Tools with QC Mode, Data Recording, Auto Calibration, NDT for Metals, Glass, Ceramics, Plastics https://a.co/d/2h1DoUp

Its over 10" to the center of the box.Yep, I have an ultrasonic thickness measuring tool.

I use it to measure the thickness of piston crowns when I need to fly cut valve reliefs into them and also when reworking the squish areas.

you could also use something like this with a 1-2-3 block:

224ARLZ Interchangeable Anvil Micrometer Set

The Starrett 224, 224M Series Interchangeable Anvil Micrometers feature a wide range of measurement and flexibility. Each micrometer is equipped with a series of easily interchangeable anvils, thus providing the full range in steps of 1" or 25mm with a single micrometer. This model features 2-6"...www.starrett.com

someone out there might also make a 1” mic with a deep throat, but I’ve never seen one. But that doesn’t mean there isn’t one out there…