- Joined

- May 7, 2014

- Messages

- 776

Hi everyone,

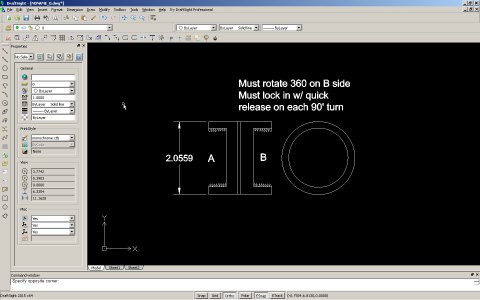

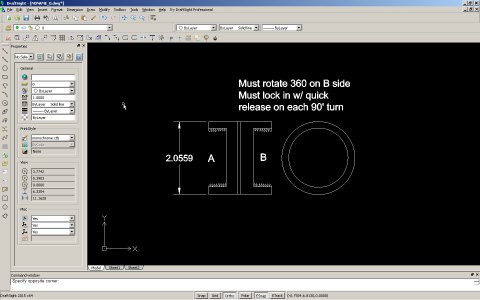

My son is making something and needs a key part. He struck out and asked me if we could buy this or something similar. If we need to make it, we're not sure how to really approach it due to the rotating and snap-lock requirement.

A picture is below. There is an A side to thead into. Same on B side. when he puts this between his latest project, he can rotate it in 90 degree increments w/ a snap-lock type feel. Then a release or pressure turn to the next position. We can adapt the opening sizes on each end - But need a minimum of around 1.5" to 3" or so.

I've looked on several sites. McMaster, Grainger and a few specialty sites. I simply am not sure what you call this.

My son is making something and needs a key part. He struck out and asked me if we could buy this or something similar. If we need to make it, we're not sure how to really approach it due to the rotating and snap-lock requirement.

A picture is below. There is an A side to thead into. Same on B side. when he puts this between his latest project, he can rotate it in 90 degree increments w/ a snap-lock type feel. Then a release or pressure turn to the next position. We can adapt the opening sizes on each end - But need a minimum of around 1.5" to 3" or so.

I've looked on several sites. McMaster, Grainger and a few specialty sites. I simply am not sure what you call this.