-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My Used - Newly Acquired - BANDSAW

- Thread starter AdvenJack

- Start date

- Joined

- Oct 31, 2016

- Messages

- 2,645

The boat in the picture is a North Sea 27 designed by Lyle Hess and made out of fiberglass. It is very heavy for its length with deep draft. Virtually impossible to build that transom out of wood. Boats with curvy transoms are commonly called double enders and suffer significant performance losses compared to boats with straighter/flatter runs aft. Without going into boring detail sailboats have a maximum speed in most conditions of 1.34 times the square root of the length of the waterline. For easy math a boat with a 25' LWL has a theoretical top speed of 6.7 knots. Because of the curve of the transom on a double ender the effective waterline is shorter than the actual waterline resulting in a lower speed potential. A long flat run aft does just the opposite. The longer flat run basically tricks the water into thinking the boat has a longer waterline giving a higher speed potential.

How do I know this stuff. In college I thought about studying to be a naval architect. After engaging in an extensive self study I decided to plug along with my degree in real estate. Boat design can be fascinating if that's what interests you. In pre computer days the calculations were extremely tedious and time consuming.

How do I know this stuff. In college I thought about studying to be a naval architect. After engaging in an extensive self study I decided to plug along with my degree in real estate. Boat design can be fascinating if that's what interests you. In pre computer days the calculations were extremely tedious and time consuming.

- Joined

- Jul 19, 2013

- Messages

- 590

Boats with curvy transoms are commonly called double enders and suffer significant performance losses compared to boats with straighter/flatter runs aft...

Simply not so.

My last sailboat was a production version of a famous racer which won the prestigious Sydney-Hobart race 3-years in a row; that is overall winner, not corrected time. That boat was called Freya, a double-ender.

- Joined

- Oct 31, 2016

- Messages

- 2,645

Freya 39's are great, comfortable boats. But a lot has changed in boat design in the last 50 years. The Sydney Hobart race crosses the Tasmania Sea. One of the nastiest stretches of ocean anywhere in the world. Often the winning boat is more about surviving the nasty conditions than speed. The current nine time winner of the Sydney Hobart is Wild Oaks XI. No money was spared in the design and construction of Wild Oats XI If a double ender was the shape of speed Wild Oats would have had a double ender transom. Here is a picture of its transom.

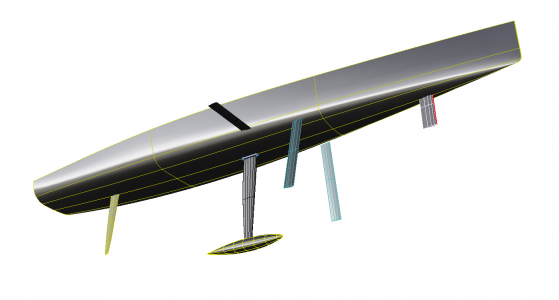

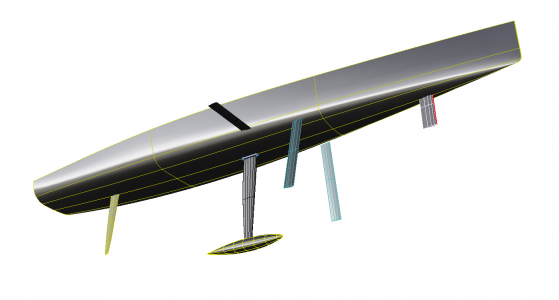

Here is a drawing of the current hull of Wild Oats XI.

For comparison here is a picture of a Freya 39 hull. Sorry for the fuzzy picture. It was the best that I could find in a quick search.

The most recent trends in the quest for speed are foils that literally lift the hull out of the water.

Sorry to hijack this thread.

Here is a drawing of the current hull of Wild Oats XI.

For comparison here is a picture of a Freya 39 hull. Sorry for the fuzzy picture. It was the best that I could find in a quick search.

The most recent trends in the quest for speed are foils that literally lift the hull out of the water.

Sorry to hijack this thread.

- Joined

- Nov 15, 2016

- Messages

- 943

Very sorry to annoy you Mickri but New Zealand is retaining the America Cup.

- Joined

- Oct 31, 2016

- Messages

- 2,645

No annoyance. If my memory serves me correctly the majority of the crew members on any of the Americas Cup boats no matter what nation the boat is from have been from New Zealand. You guys down under have some of the best sailors in the world bar none.

MICKRI: I'm in agreement that the fastest hull design at this point, is what you are presenting.

I must confess that speed is one of the aspects that's only clumped into the middle group of my list,

as far as importance goes. I'm thinking that wood/lapstrake is not the best choice for the primary

material and construction method if speed is the number one desired aspect. But I'm going the

wood/lapstrake path. And yes, it's all true what you said about the "ocean voyage capable" Nor'Sea

27 footer. Except, I've seen with my own eyes some very rounded aft sections that have been built

with wood - lapstrake construction. AND THEY MELT ME. I've not seen the boat below in person,

but WOW! I guess I'm taking a "Starry Eyed" route on this boat build, with heavy influence coming

from the traditional Scandinavian sailboats.

EZDUZIT: Regarding FREYA 39 It looks like it could go to war against the ocean... and survive!

And I mean that in the Most FLATTERING WAY !!!

NORTON DOMMI: I consistently hear ALL GOOD THINGS about New Zealand. I'm sure I'd enjoy myself there!!!

I must confess that speed is one of the aspects that's only clumped into the middle group of my list,

as far as importance goes. I'm thinking that wood/lapstrake is not the best choice for the primary

material and construction method if speed is the number one desired aspect. But I'm going the

wood/lapstrake path. And yes, it's all true what you said about the "ocean voyage capable" Nor'Sea

27 footer. Except, I've seen with my own eyes some very rounded aft sections that have been built

with wood - lapstrake construction. AND THEY MELT ME. I've not seen the boat below in person,

but WOW! I guess I'm taking a "Starry Eyed" route on this boat build, with heavy influence coming

from the traditional Scandinavian sailboats.

EZDUZIT: Regarding FREYA 39 It looks like it could go to war against the ocean... and survive!

And I mean that in the Most FLATTERING WAY !!!

NORTON DOMMI: I consistently hear ALL GOOD THINGS about New Zealand. I'm sure I'd enjoy myself there!!!

Last edited:

- Joined

- Oct 31, 2016

- Messages

- 2,645

That is one beautiful boat. Looks like a Dutch design. Have you been to the wooden boat forum? Lots of good info there on building wooden boats. Put your ideas and wants up on the wooden boat forum and they will keep you headed in the right direction.

Have fun with your build.

Have fun with your build.

- Joined

- Oct 13, 2014

- Messages

- 6,703

I've now seen guys on videos using a table saw to do portions of the resawing work on every board! Start with

my basic "learning" board. (2x6 and 16 feet long, so it's true height is 5.5 inches) On a table saw make a full, 16' length, kerf cut,

2 inches deep, into one of the 1.5" wide edges.Then flip the board, and into the opposite 1.5" edge, make a second kerf cut 2 inches

deep, directly aligned with the first kerf cut. The result will be, that ONLY the center portion of the board remains to be cut with the

little Delta *10 inch bandsaw, and the thickness of that remaining wood is just 1.5", the same as any typical rip cut or cross cut!! Hooray!

If you have a 10" table saw, the blade should make it to the center of the board, thus you wouldn't even need the bandsaw. If the table saw lacks sufficient horsepower to do it in 2 passes you could go 3 or 4 passes. The finish might even be good enough to not need planing or very little. A good sharp blade designed for ripping is your friend. I have re-sawed many a board like this, it's reasonably safe if done competently. Also get a couple of roller stands (HF has decent ones for cheap) they make feeding 16' stock a breeze.