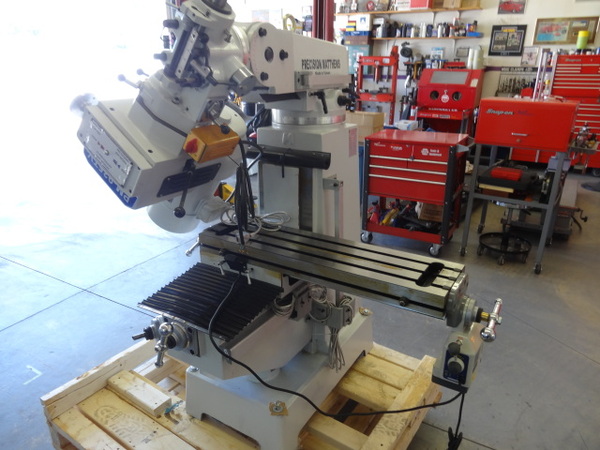

My PM935TV knee mill finally arrived last Tuesday and I have spent a few days last week getting it set up and personalized a bit.

First off, I must say that now after having it for nearly a week it is everything I had hoped for. The quality is extremely high end and compliments my PM1340GT very nicely.

I will admit that when the driver backed up to my shop and opened the door, my stomach jumped into my throat and I wanted to strangle the driver. The mill had tipped over onto its' side, broken through the pallet and was leaning against the inside of the truck box. It didn't go all the way over onto its' side but more horizontal than vertical. Evidently the driver was a bit aggressive at driving and the mill had pulled the four large lag bolts right up and out of the pallet it was sitting on. I jumped all over the driver and asked if he didn't see the large "TOP HEAVY" lettering on each of the four sides of the crate. Needless to say I did NOT tip the driver on this delivery.

He wanted to close up the truck and bring it back to their dock and get it stood upright with a forklift. Although a forklift would have been the best alternative, I didn't think it would make it another 30 miles back to Salt Lake City without going the rest of the way over and for sure creating more damage. I also didn't want to wait another 5-months to get another one. I wanted to get it upright and inspect prior to making any definitive decision.

Here is how it showed up at my home/shop.

After removing three sides of the pallet/crate to get a better look.

Luckily my son had just gotten home and was able to help me because the driver was absolutely worthless as far as helping. All he wanted to do was bring it back to their Salt Lake City transportation hub and really didn't want me messing with it. My son and I got the engine hoist up into the back of the truck and strapped the top of the column. We raised it about as far as we could with the hoist and got the weight up off of the head and away from the side of the truck so I could get a better visual of it. All I could see at this point was the small handle for the RPM that was broken. I was able to push it the last few degrees to get it vertical and standing back on the pallet flat on its' base. We shifted/jockied it around so I could drive the lag bolts back into the pallet and then we used a 10k pound ratchet strap to secure it to the pallet.

Once we got it out of the truck, on the ground and somewhat in place in my shop we removed the remainder of the plastic wrapping and did a thorough inspection. Unbelievably there was NO damage with the exception of the small handle for the dial. I called QMT and Matt was busy but I informed Nicole about what had transpired and she was awesome. After speaking with Matt she called back to ask a few more questions and I forwarded the pictures that I had taken to Matt.

Here it is close to its' new home in my shop.

This was the only damage. No big deal and Matt was great to get a new one in the mail immediately.

I got the pallet cut down so I could lift the mill off of the pallet and get it sitting on the floor. I then commenced on taking measurements for a base. I needed to get the mill a few inches up to make it more comfortable. After exchanging information with a few members of the forum who already own this machine I had originally decided I was going to build a base that was 4" in height combined with leveling feet which were 2" for a total of 6" overall height gain. I really liked the height in which it was sitting on the pallet which was closer to 8" overall height. That did it for me, so I embarked on fabricating a base that would raise the milling machine a total of 8". The base would bolt directly to the bottom of the mill yet be slightly wider at the footprint and employ leveling feet.

I started with some 2"x4"x.125" rectangular tubing and some 2"square tube x .125" wall.

I machined some threaded bungs and welded them to the rectangular tubing to anchor the mill to the base.

I then welded the 2" square tubing to the 2"x4" rectangular tubing as well as gusseted it for strength.

Base completed, painted and sitting in front of the milling machine ready for installation.

And there she is, sitting on her new base in her new home.

So far this all took place on Tuesday. The truck backed up to my shop door just before 2:00PM and by 7:30PM it was sitting in its' final resting spot.

Now on to Wednesday morning. I took a couple of days off work to get it all set up and put my shop back together so I wanted to get right after it. I installed my 220VAC/30amp plug and she purred like a kitten. So nice and smooth running. I noticed immediately that none of the collets fit in the spindle and I kind of was expecting that due to other threads that I have read.

Here is how to remedy that. There is a small set screw on the back side of the quill that must be loosened to remove the collar.

Next use a spanner wrench to remove the collar.

Once the collar is broken loose it should spin out freely by hand.

Collar removed.

Once the collar is removed there is a set screw with another one under it. The top one is a locking set screw, remove it. Then back the inner one out just enough so that the collets, drill chucks and other tooling will fit into the spindle/quill freely. Once you are happy with the fit, install the outer set screw and tighten. Then reassemble everything in reverse order.

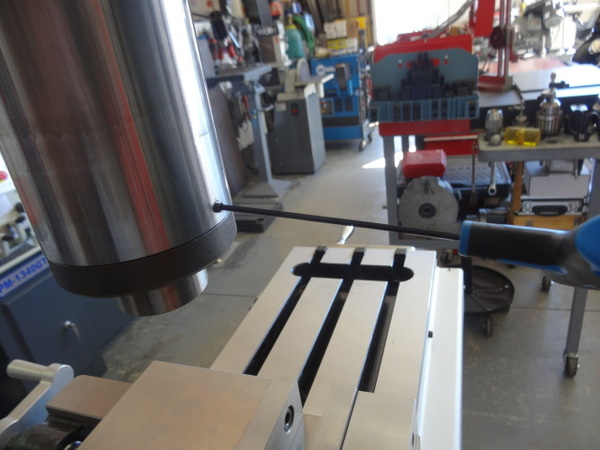

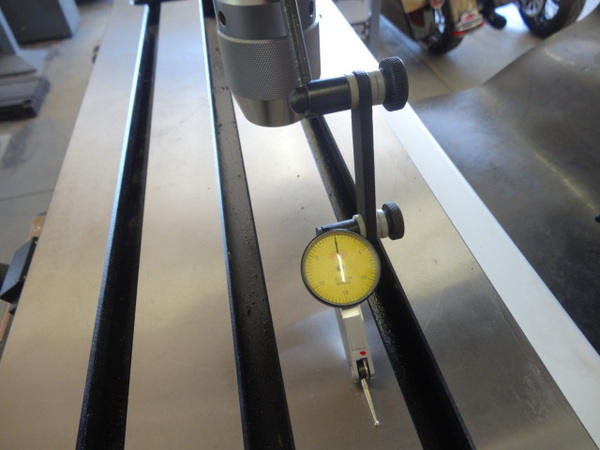

Now on to tramming the head. Got her dead on in both axis.

I also installed the Eason ES-8A onto the machine and got it all hooked up and operational.

More to follow.

Mike.

Congrats for your new mill. It looks very nice. You have a terrific shop.....I wish mine could be that big and clean. Like the base you made for the new mill, I need one for mine.....need it a bit higher....no good to bend your knees or back to reach the front handwhell.