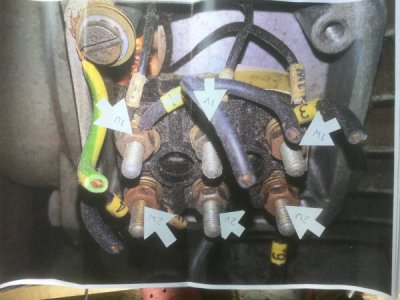

Wow! Someone should be punished for this. It looks like it was very nice before it was left outside.

Let's hope it's "just" surface rust. But my first choice of tool would NOT be a steel brush.

Rather like steel wool and some chemicals.

When you take it apart, do take a lot of pictures and lay the parts out in order, subassemblies.

I am sure someone here will get you a full manual - I'll see, if I should happen to have one.

But I have some Bantam change wheels, if you're interested. Not a full set, but maybe enough.

Cheers

Erik

On edit: I have a spare parts catalogue with exploded drawings of the lathe.

And I just found a full english manual. Both in the PDF file format. PM me, if you want them.

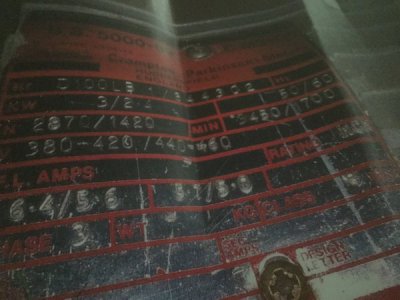

BTW, it looks like it's an imperial machine, not metric. A cheap DRO would help.

I am interested but i have to wait until i know more about my lathe and what i realy need.

How many change wheels did i realy need to do metric screwcutting