Hello everyone I own an Enco knee mill that is nearly identical to the model grizzly currently sell. I am going to document and ask questions about my installation of a Chinese three axis DRO system.

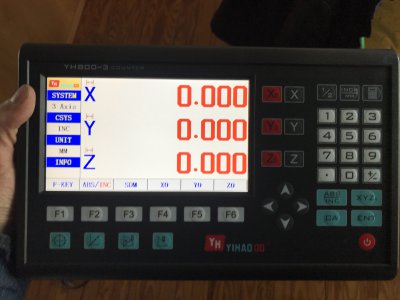

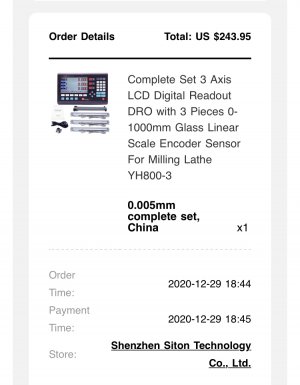

First things first I don’t know how many of you have purchased from Ali express but this was my first time and I had some caution. The transaction was incredibly smoothly I noted the length of the scales I wanted in a message to the seller, they were cut correctly and arrived in several weeks. I opted for one of the displays with a color screen and several functions. I figured if I was going to the trouble I might as well get all the functionality I can. The cost is frankly very low either way. I believe the scales are cross compatible should I ever want to upgrade or on the contrary find that the more complex display has issues but I don’t really anticipate either of those based on what others have told me.

Only issue is they sent the wrong (AU I believe?) power cable. Not really an issue, I have lots laying around.

In the next posts Ill describe how I installed a bump stop and the Y axis then will be back with some questions about the X.

First things first I don’t know how many of you have purchased from Ali express but this was my first time and I had some caution. The transaction was incredibly smoothly I noted the length of the scales I wanted in a message to the seller, they were cut correctly and arrived in several weeks. I opted for one of the displays with a color screen and several functions. I figured if I was going to the trouble I might as well get all the functionality I can. The cost is frankly very low either way. I believe the scales are cross compatible should I ever want to upgrade or on the contrary find that the more complex display has issues but I don’t really anticipate either of those based on what others have told me.

Only issue is they sent the wrong (AU I believe?) power cable. Not really an issue, I have lots laying around.

In the next posts Ill describe how I installed a bump stop and the Y axis then will be back with some questions about the X.

Attachments

Last edited: