- Joined

- Apr 28, 2014

- Messages

- 3,590

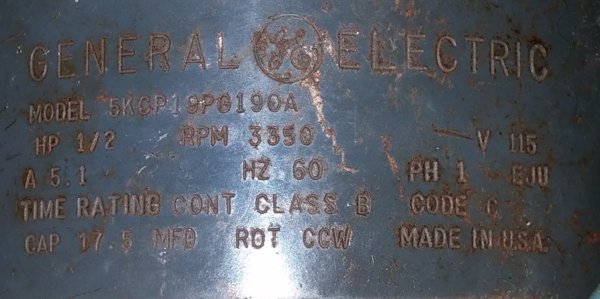

I need some assistance in properly wiring up this motor. I am thinking of setting it up as a 'Foredom' type tool.

I've got a few hand pieces and am hoping I can get one to work for polishing wheels.

The motor has been kicking around for over 20 years, and I even forgot I had until I was unpacking an old box of clutter.

Firing it up 'as-is', it spins up nicely. However there seems to be a 50-50 chance of which direction the shaft will rotate. The labeling states CCW but it is going in both directions.

I figure that I need a capacitor or something a bit more than just an extension cord spliced to it.

Thanks!

I've got a few hand pieces and am hoping I can get one to work for polishing wheels.

The motor has been kicking around for over 20 years, and I even forgot I had until I was unpacking an old box of clutter.

Firing it up 'as-is', it spins up nicely. However there seems to be a 50-50 chance of which direction the shaft will rotate. The labeling states CCW but it is going in both directions.

I figure that I need a capacitor or something a bit more than just an extension cord spliced to it.

Thanks!