- Joined

- Jan 29, 2017

- Messages

- 311

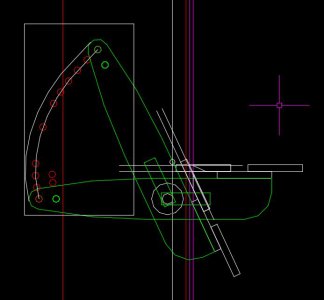

Starting to make sense now . Seems like all wear takes place on the sides of the shaft journals as the load is concentrated on those points depending on which way you are steering to turn.

Over time as wear increases the cross section of the journal becomes oval shaped.

Therefore if the rudder is pointing at 180 degrees to direction of travel most of your wear will show up at 90 and 270 degrees which will measure less than at 0 and 180 degrees.

I can't see an easy solution to fitting new bushes unless you machine the shaft journals round again as the rudder and shaft will destroy the new bushes in a short time.

I think your friend is up for a new rudder assembly.

Over time as wear increases the cross section of the journal becomes oval shaped.

Therefore if the rudder is pointing at 180 degrees to direction of travel most of your wear will show up at 90 and 270 degrees which will measure less than at 0 and 180 degrees.

I can't see an easy solution to fitting new bushes unless you machine the shaft journals round again as the rudder and shaft will destroy the new bushes in a short time.

I think your friend is up for a new rudder assembly.