Hi chuck,

Here is the info, if you decide to build one.

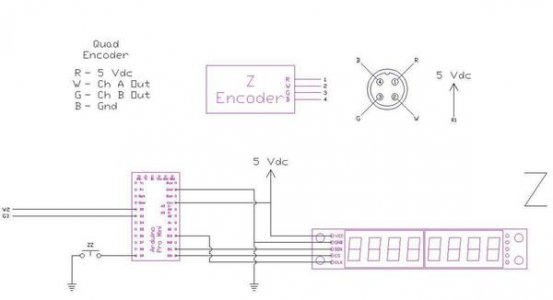

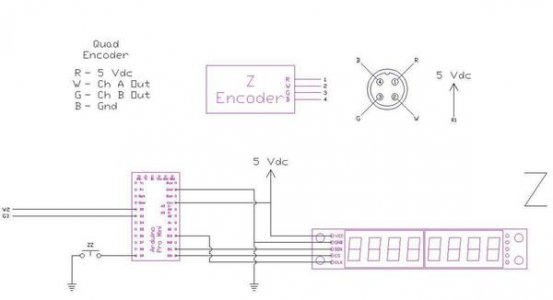

Electronics

Encoder: LPA3806 Rotary Encoder two phases 600 pulses/rotation

Arduino: Pro Mini Atmega328P 5V 16 MHz

Display: Max7219 8-Digit display module

Power Suppy: 5 Vdc 1 A min

Programming:

USB Serial: FT232RL Usb to Serial adapter

Hardware:

Pulley

Spring

Bearing

Timing Belt

Timing Pulley

Arduino Code:

Attached file MillDROZ.txt (copy it to your Arduino system folder and rename it to .ino)

Drawing:

Attached file Encoder.txt (rename it to Encoder.dxf - the forum don't allow dxf files...)

Diagram:

You will need to download the Arduino IDE platform and learn the basics of it.

The Arduino Pro Mini is a simplified version of the traditional Arduino UNO. It has no USB port (cheaper and much smaller), but needs a adapter for programming, the FT232.

The USB to Serial adapater FT232 is used only for programming the Arduino Pro Mini. It is not used in operation; you will need only one for all your Arduino Pro Mini projects.

Wagner