- Joined

- Nov 6, 2012

- Messages

- 128

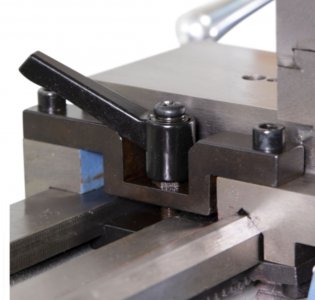

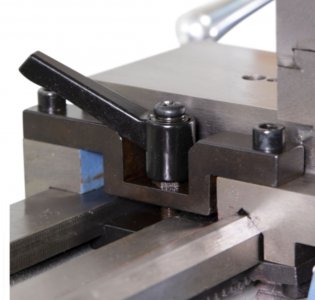

I put this Carriage Lock on my LMS 4200 7x12 mini-lathe. It’s fine for acing when locked down, but when unlocked for turning, the handle is loose and jiggles around. I snapped the handle off on a run when it jiggled forward under the spindle and hit a lathe dog.

Did I have it set up wrong? It’s tight over the read bolt when locked (as in the picture below) but when unlocked, does not remain in position over the rear bolt.

Did I have it set up wrong? It’s tight over the read bolt when locked (as in the picture below) but when unlocked, does not remain in position over the rear bolt.