- Joined

- Jul 26, 2011

- Messages

- 4,142

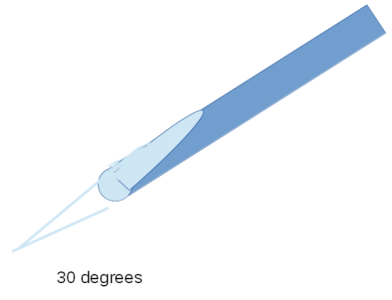

I make them by FIRST hardening a piece of drill rod and drawing it to a light brown color. THEN I grind a long angle of about 30º on the end of it. I grind after hardening because the hardening process can,and usually will warp the reamer a bit,because there is a different amount of surface area on either side of an already ground reamer. The reamer is just fed into the hole,and will cut very cleanly and nicely. Don't try REVERSING the reamer when withdrawing it. This can jerk a chunk out of the angled cutting edge. You don't reverse modern reamers either,for that matter. Keep them rotating in the same direction as before while withdrawing them.