- Joined

- Dec 22, 2020

- Messages

- 97

Atlas 6" 10100 lathe would like to order new Timken tapered roller bearing

I've never bough bearings before, and I do not know that much about them anyways. Does anyone know the part numbers to order for an atlas 10100 lathe, think blue paint :) I did search the forum yesterday and found people looking for them but I never saw a specific part number or a link to a...

www.hobby-machinist.com

www.hobby-machinist.com

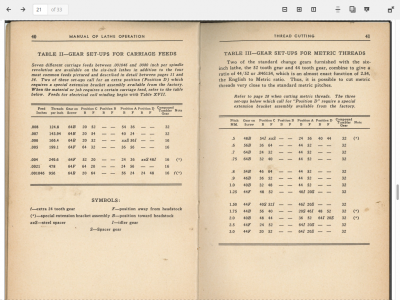

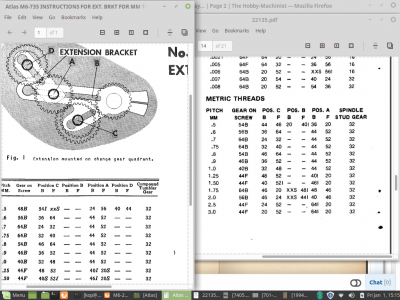

Bearings Bushings Atlas Lathes & Mills.pdf

List of spindle bearings and bushings for Atlas and Atlas/Craftsman lathes and mills

www.hobby-machinist.com

www.hobby-machinist.com

The 2 cups are Timken 07196, the front cone is Timken 07100, the rear cone is Timken 07079.

Okay, with all that I had my bearing guy "whip something up" If I can't find the receipt I may still have the boxes with the old bearings in them. I wonder why I do that knowing I'll never re-use those bearings but...