- Joined

- Feb 27, 2024

- Messages

- 6

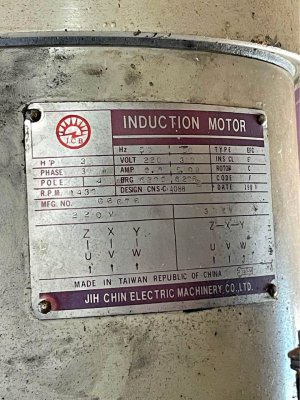

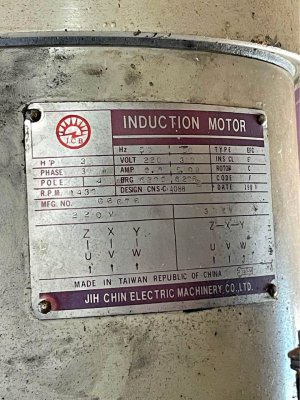

I'm in the market for a mill, I'm trying to put together a shop. I am in rural Missouri, and its kind of slim pickens for used machinery and storage/garage finds. I considered buying a benchtop mill because I am just getting tired of looking. I came across this machine today, but dont know anything about it. Its an older import from the looks of it, and they claim it works(or did work before it became a ton paperweight) they also said it was set up to cnc. Just looking for any input, and maybe what im getting myself into if it is possible to refurb it. Im attaching the images. Thanks in advance. Also, glad to be here, this is actually my first post. I hope I can contribute back once I gain some more knowledge.