- Joined

- May 3, 2017

- Messages

- 1,997

Richard,Nice Machine, I love mine. It's one of those machines that when you need it, nothing else will do! Here is a picture of the capacitor on mine, they are the same machine, so it should show what you need.

RichardView attachment 319836

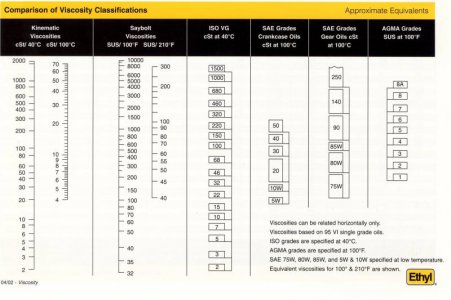

Can you offer any input on the oil pump issue? Does the pump on your South Bend work? Any idea short of filling the reservoir on how to test it? What type oil do you use?

Anything you can offer would be greatly appreciated.

Regards