Herev are some pics of a locomotive project I've been working on. I've done quite abit already and here is where I'm at now.

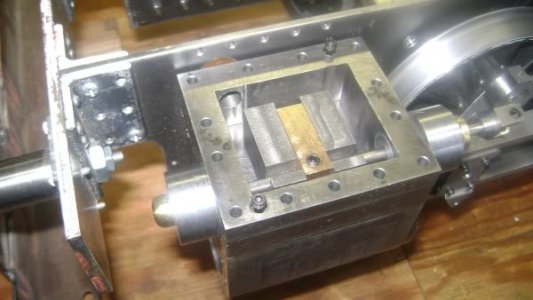

I have made the cross heads and profiled the cyls and mounted them. Pics follow.

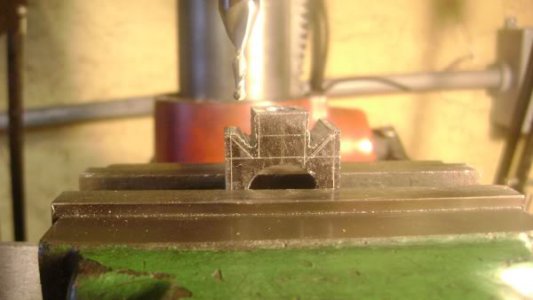

Set the cross heads up in the mill and machined to lines basically. I used a 1/8 ball end mill here.

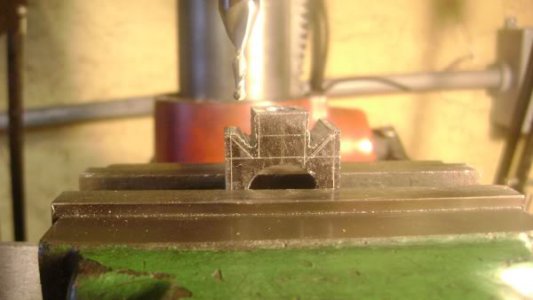

Changed to a 3/16 end mill here.

I silver solder bronze slippers on them and silver soldered the backs on too.

I riveted in the drop link pins to the front of the cross head. I took a page out of Dr. Johns way of doing things and milled the front plate from solid instead of trying to bend the off set for the pin.

I turned the piston rod ends of the cross heads in the lathe but for got to take pics.

Ron

I have made the cross heads and profiled the cyls and mounted them. Pics follow.

Set the cross heads up in the mill and machined to lines basically. I used a 1/8 ball end mill here.

Changed to a 3/16 end mill here.

I silver solder bronze slippers on them and silver soldered the backs on too.

I riveted in the drop link pins to the front of the cross head. I took a page out of Dr. Johns way of doing things and milled the front plate from solid instead of trying to bend the off set for the pin.

I turned the piston rod ends of the cross heads in the lathe but for got to take pics.

Ron