- Joined

- Jan 9, 2016

- Messages

- 120

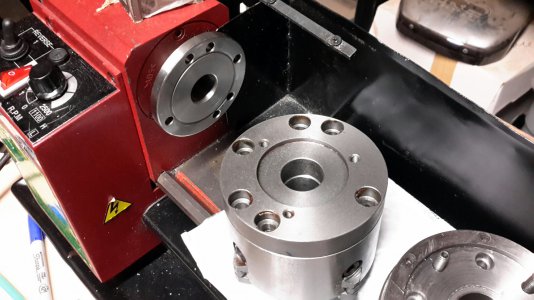

I ordered a 4" 4 jaw chuck for my 7x10 HF lathe. The included adapter plate has the correct 3 stud hole pattern, but the recess (register?) is only 55mm and does not fit on my 80mm spindle.

My understanding is that the recess does the alignment work, and the studs are there to clamp it down.

So... what gives? Do I have the wrong adapter plate, or is that just how it works with this size lathe?

Sorry if this is a dumb question, but it seems to defy my particular brand of logic.

Thanks!

My understanding is that the recess does the alignment work, and the studs are there to clamp it down.

So... what gives? Do I have the wrong adapter plate, or is that just how it works with this size lathe?

Sorry if this is a dumb question, but it seems to defy my particular brand of logic.

Thanks!