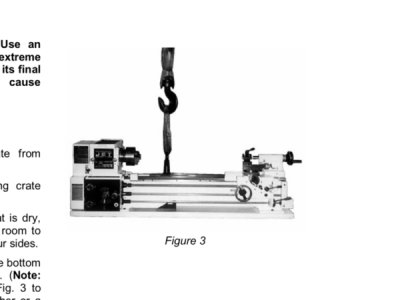

You guys are right about lifting with the strap behind the leadscrew. Yesterday I was in a lot of pain,heavily drugged with pain killers,and not thinking too straight.

It has been years,many years,since I lifted a bench lathe. My current lathes are much larger. They were moved with fork lifts.

We did have to move an 8000# lathe 15' across a concrete floor at work,and rotate it 180º. I used a come along and 1/2" mild steel rollers under the pedestals to move it,after first getting the floor very clean(Those rollers had to roll over any stuff that might have been left on the floor.) Fortunately,we had an "I" beam column in the middle of the floor to secure one end of the come along to. That was a huge help!!

It was fun. We felt like we were making the pyramids!

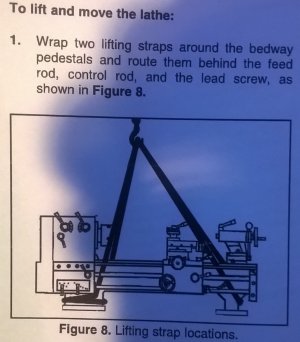

Your steel plates with eye bolts are a great way to go. Do be careful of straps going around castings inside the bed. Those can have flashings on the castings that can cut the corner of a strap and cause it to tear in half. Best to wrap a rag under the strap if you are going around castings. I had a strap tear lifting a bridgeport type mill. once. It was wrapped around the ram in front of and behind the column. Somehow,it managed to start tearing when a guy was fork lifting the mill through our double doors at work. I saw it tearing and had him put the mill down at once. The strap belonged to the warehouse,and I'm sure it was an import. I bought them a new one.

Joshua,I lived in Amarillo when I was in the first grade. We were pretty poor,and lived in a single car garage on South Garfield Street. I "Google Earth'ed" The house is still there,but no trace of the former garage,chicken coop,or out house in the back yard(which we used).