- Joined

- Nov 25, 2015

- Messages

- 8,320

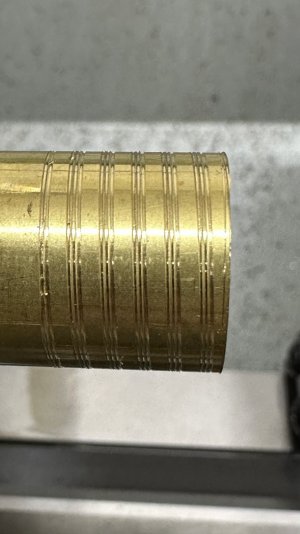

ok, it is possible, but mine are not as pronounced.

I did multiple tests.

about to post a video, I had slight mis-track on my 3rd attempt. But very slight.

edit: it's loading now.

I did multiple tests.

about to post a video, I had slight mis-track on my 3rd attempt. But very slight.

edit: it's loading now.