- Joined

- Nov 17, 2020

- Messages

- 1,723

Ok.. so i have been looking at motors and such for a while since i had gotten this lathe home. The original motor is a 440v 3ph motor. On another forum, i was told that a Lesson 192241 was a direct replacement. Come to later find out that that motor has been discontinued, there are still some sitting in warehouses, best price i found was 384.xx..

So yesterday, i decide to take the original motor to the local armature shop. They said that they could open it up and see if it can be rewired to 220v 3ph, but there lead time is pretty long right now. So, the fella there (the only one working in the shop at the time) has to help another customer. While i am waiting, what do i spy on the shelf.. none other than a brand new Lesson 192241 motor, 220v 3ph. And the price was right too.. let me have it for 300.xx out the door.

So now, i have it mounted right now for clearance check and what not. It is a lil longer than the original Elin motor, but i feel that i will be ok.. I am going to purchase a WJ200 VFD, as to which one, the 007 or the 015.

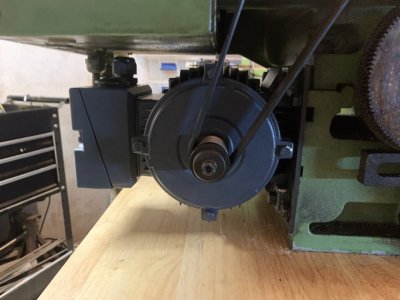

Here is a look at the motor installed

As you can see here, might have an issue with getting the wires to it, but i don't think that it will be that "big" of a deal

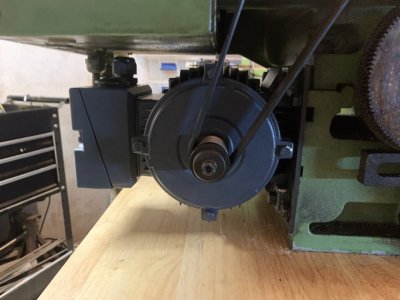

And from the front

More in a bit

So yesterday, i decide to take the original motor to the local armature shop. They said that they could open it up and see if it can be rewired to 220v 3ph, but there lead time is pretty long right now. So, the fella there (the only one working in the shop at the time) has to help another customer. While i am waiting, what do i spy on the shelf.. none other than a brand new Lesson 192241 motor, 220v 3ph. And the price was right too.. let me have it for 300.xx out the door.

So now, i have it mounted right now for clearance check and what not. It is a lil longer than the original Elin motor, but i feel that i will be ok.. I am going to purchase a WJ200 VFD, as to which one, the 007 or the 015.

Here is a look at the motor installed

As you can see here, might have an issue with getting the wires to it, but i don't think that it will be that "big" of a deal

And from the front

More in a bit