Hi Charles

I thought one needed some sort of reliable thing to signal when the power feed lever is in ON position, which provides the first half of the logic.

The next thing that needs to be sensed is when the carriage really must not be going any closer (under power). Something that will take it out of trouble before it hits the solid stop. The closed limit switch riding on the carriage stop provides that, and it will move, along with the stop, to wherever you set it.

Mechanically, it could be a coaxial tube, or qa separate rod o whatever, but the key thing is that it operates a bit before the carriage hits the stop, while not actually stopping anything if the carriage is being moved safely by hand.

Let us ignore complicated stuff like using an actuator to yank the feed lever out of engagement. The simpler, cheaper, way, that gets your attention, is to just wire the two switches in series with the lathe E-Stop. Spring load a rod if you like, but youu don't have to. You can avoid avoid crushing the limit switch by using one of the many switch shapes with lever bumps that can operate the switch as it "passes by".

Dynamic braking is a refinement if the lathe keeps coasting to a halt from inertias. If the limit has a sufficient gap to the hard stop, it will work anyway.

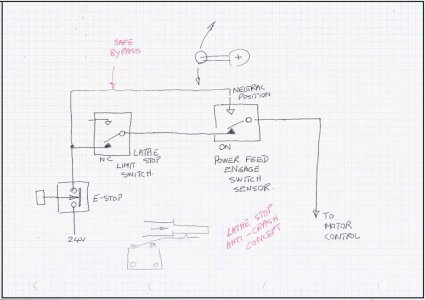

View attachment 401780

OK - it's a quick 'n dirty scribble that may not yet be mutt's nuts, but the idea is that if the power feed is in a "safe" position, i.e. not engaged, the anti-crash limit switch is bypassed via the NO (normally open) contact on the power feed sensing switch. If the power feed is engaged, it will have to obey the anti-crash limit switch, which can be set with some gap before the hard stop. If you ride into it with the power feed lever ON, the lathe will stop

before it rides into the hard stop.

I am sure that folk here can come up with refinements, and all manner of various tidy mechanical arrangements that will do this, but it's a start.