- Joined

- Jun 23, 2011

- Messages

- 786

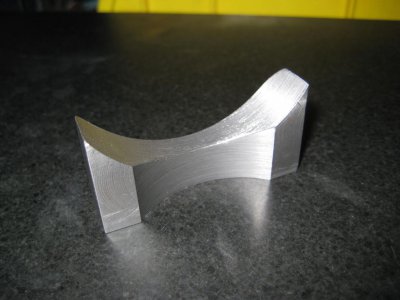

If I were to make dozens of threading tools with the tip dressed as you ask, I'd probably just dress a wheel with the correct profile and go to it. I could use this fixture to hold the bit for that... Yes, one would not need to compute the angle...

But that would be overkill for just one or two.

I usually just grind that end dress by hand or leave it sharp...

John

But that would be overkill for just one or two.

I usually just grind that end dress by hand or leave it sharp...

John