- Joined

- Dec 17, 2012

- Messages

- 745

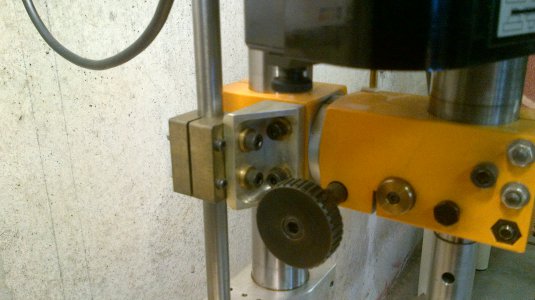

I've seen there are hand knurlers, like the one sold by Enco: http://www.use-enco.com/CGI/INPDFF?PMPAGE=215&PMITEM=250-1715

I've tried to make a similar one using an old pipe cutter and two knurling wheels I got on eBay, but the attempt was unsuccessful: all I got was scratched metal with just a ghostly diamond pattern .

.

Since sometimes it would be nice to have knurled knobs, is there a source of knurled rod, which can be simply cut, drilled and tapped to the size I want, without to have to buy complete (expensive!) knobs, hard to find in the right size?

I've tried to make a similar one using an old pipe cutter and two knurling wheels I got on eBay, but the attempt was unsuccessful: all I got was scratched metal with just a ghostly diamond pattern

.

.Since sometimes it would be nice to have knurled knobs, is there a source of knurled rod, which can be simply cut, drilled and tapped to the size I want, without to have to buy complete (expensive!) knobs, hard to find in the right size?