-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Knurling Question

- Thread starter prasad

- Start date

This type of knurling is a forming process not a cutting process, if you are developing chips something is already off.

There are cut knurling tools which work a charm and require less load on the machine itself. The cost will scare off most hobbyists I suspect.

http://www.mscdirect.com/product/details/03298635

At that price specially

- Joined

- Sep 29, 2014

- Messages

- 2,102

It appears that most of the US Companies that stuck with producing tools for manufacturing and never dabbled in the consumer/hobbyist market are doing fine. Dumont for example, can't buy their broaches and bushings at home depot I suspect.American tool companies wonder why people are looking for alternatives to their over priced tools!

A tool that can produce 200 parts per day for weeks repeatably without fail is worth a bit more to the purchaser then a tool that will fail often or make inconsistent product. Another interesting aspect of American companies is that they only do one thing, they rarely use their large R&D infrastructure to develop other products. Not disparaging the auto industry at all, many advances in manufacturing processes have come from auto makers in the past.

Yamaha makes pianos. motorcycles, outboard engines, personal watercraft and small boats.

Honda makes cars, generators, motorcycles, outboard engines, lawnmowers etc.

Hyundai makes ships, heavy equipment, large engines, cars and other products

BMW makes cars and motorcycles

Kawasaki makes motorcycles and Industrial robots

General Motors makes cars and car loans.

Last edited:

- Joined

- Aug 22, 2012

- Messages

- 4,121

this looks buildable

http://www.ebay.com/itm/Hardinge-L2...t-Condition-/181907946310?hash=item2a5a8efb46

http://www.ebay.com/itm/Hardinge-L2...t-Condition-/181907946310?hash=item2a5a8efb46

- Joined

- May 2, 2014

- Messages

- 217

Sorry, Nightwing, but I don't understand. Could you elaborate on that, please?

A hard steel roll spinning on a hard steel pin will result in the two parts welding together when one component transfers a bit of its metal to the other part due to friction and heat. The carbide pin is extremely smooth and much harder than the roll, so there is less chance of the parts setting up.

- Joined

- Dec 20, 2012

- Messages

- 9,422

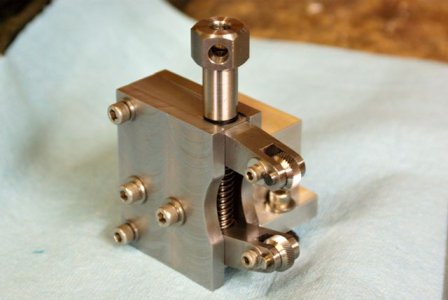

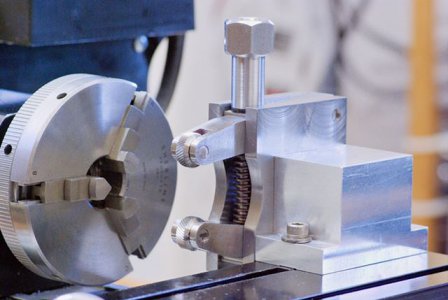

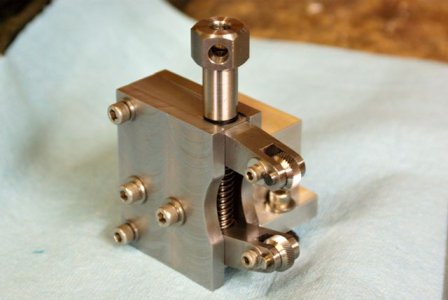

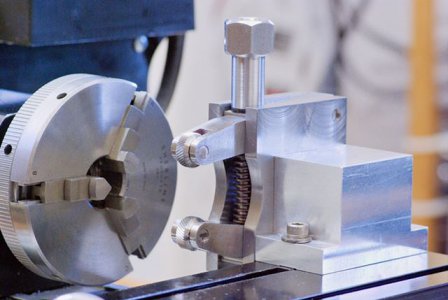

Prasad, I tried to post pics of my knurler before but was unable to do so until Nelson and Robert got to work on the problem. Now it seems to work and I can show you a simple tool I made for my Sherline lathe. It is mounted to the rear of the cross slide and will transfer to my larger lathe by changing the mount. This knurler has produced beautiful knurls in mild steel, stainless, aluminum, brass and Delrin. In most cases, it will create a full-pattern knurl on the first pass if I do my job.

I hope this gives you some ideas if you decide to make one of your own.

Edit: I forgot to add that it will knurl from zero out to 2-1/8" OD and despite having a hex shaped shank on the main screw, it tightens with simple hand pressure. Cost was almost nothing except the knurls - just stuff I had laying around the shop.

I hope this gives you some ideas if you decide to make one of your own.

Edit: I forgot to add that it will knurl from zero out to 2-1/8" OD and despite having a hex shaped shank on the main screw, it tightens with simple hand pressure. Cost was almost nothing except the knurls - just stuff I had laying around the shop.