- Joined

- Jun 12, 2014

- Messages

- 4,811

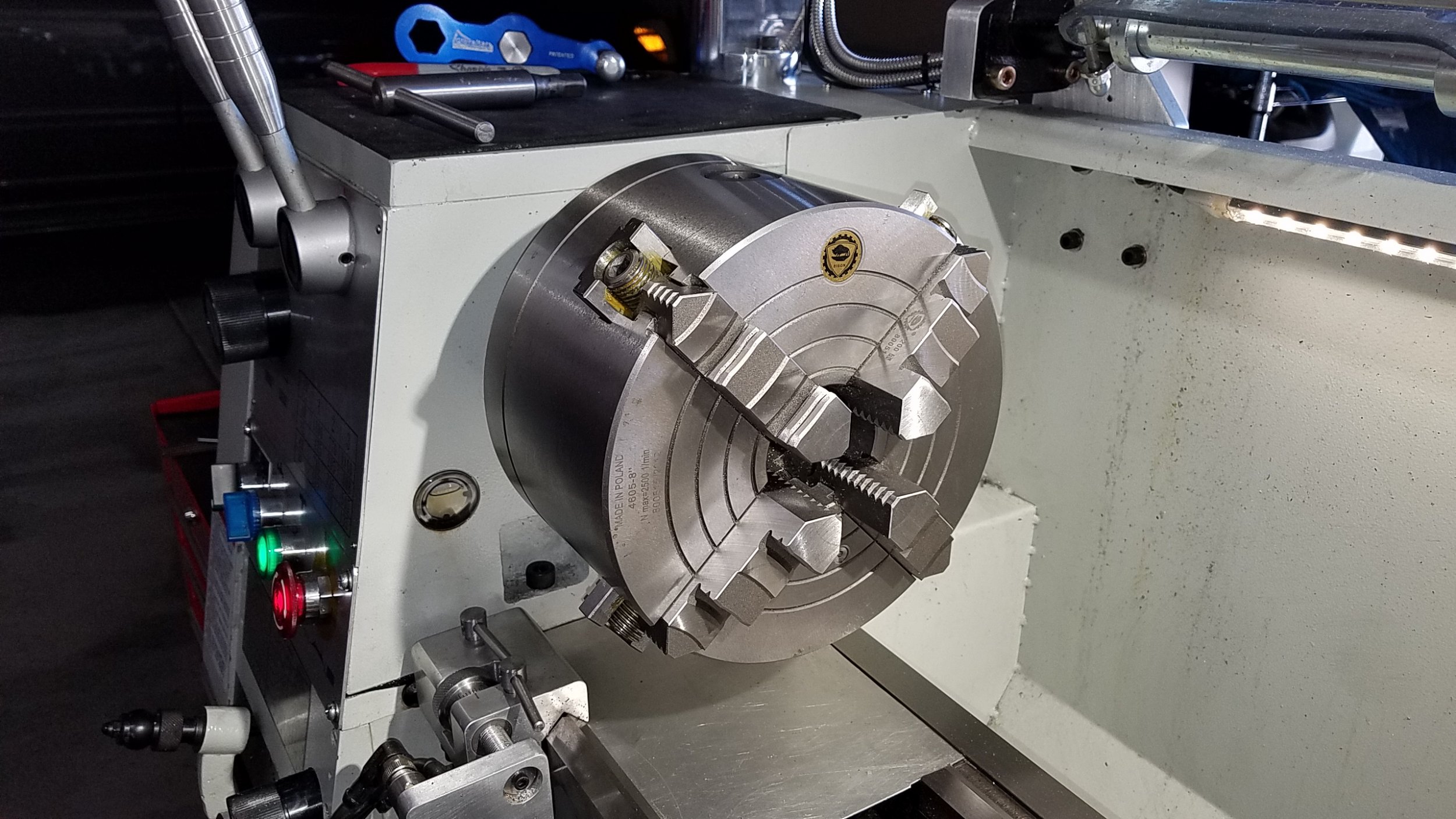

The model number listed and list price is that of the Bison combo, my old links go to that chuck. David, the travel of the independent is around 2.5", the scroll portion is a bit over 2". So by moving the jaw back plus the scroll you have close to 4.5" , but the jaw may hit the ways at that point. . I have spun the chuck up to around 2000 RPM, but usually I prefer my 5C or 6" 3J scroll for high speed work. The chuck is not any longer then a standard scroll 8" with back plate (4.5"), I do not see that as an issue vs, the pressure exerted when cutting which is further out. Below is the chuck on my 1340GT. The Gator back plate is an 8", use to be called the FLD-200D4, you would need to check with one of the chuck suppliers like Ajax Industries or Small Tools. You would need a back plate for most of these chucks except if you get a direct mount. Depending on the manufacturer, you may have to turn down the registration step slightly for the chuck to mount, but you do not need to do a face skim cut.

www.hobby-machinist.com

www.hobby-machinist.com

8" Bison 4 Jaw Combination Chuck

Nice reports guys. Mine is still in the box. I am still stuck on using the 6J set thru for barrel work when not using the front spider.

www.hobby-machinist.com

www.hobby-machinist.com