- Joined

- Sep 5, 2013

- Messages

- 3,207

Well, perhaps more than just a little!

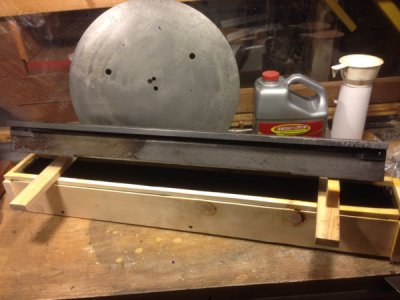

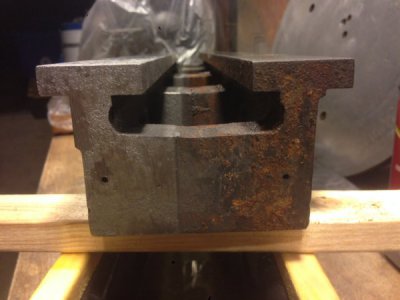

Buddy delivered this to me this morning. It's what remains of (or is the remains of, depending on how you see it) a little 6" Craftsman lathe. It saw the inside of a house fire, then sat for a year in the burned-out shell while insurance was being sorted out. It's pretty rough.

My first thought was to maybe get it going again, but that was before I'd seen it up close. Supposedly it wasn't in the area of the house that got completely burned, but there's still pretty convincing evidence that it saw some heat. Some of the Zamak parts have started to melt a bit, and there's a fair bit of scorching. But amazingly, the back gears still turn freely! I guess they were under the hood and remained somewhat protected.

Anyhow, even though it feels a bit creepy to have the thing in the shop, I'm going to tear it down for salvageable parts if any exist. I've got a running Atlas 618 as well as an new-old Atlas mill, both of which have parts crossover. I already see a countershaft assembly that isn't too far gone and there might be others. So while I don't really need another project just now, it looks like I've got one. Time to start a fresh tank of molasses....

Thanks for looking, and if anything really nifty shows up along the way I'll post the findings here.

-frank

Buddy delivered this to me this morning. It's what remains of (or is the remains of, depending on how you see it) a little 6" Craftsman lathe. It saw the inside of a house fire, then sat for a year in the burned-out shell while insurance was being sorted out. It's pretty rough.

My first thought was to maybe get it going again, but that was before I'd seen it up close. Supposedly it wasn't in the area of the house that got completely burned, but there's still pretty convincing evidence that it saw some heat. Some of the Zamak parts have started to melt a bit, and there's a fair bit of scorching. But amazingly, the back gears still turn freely! I guess they were under the hood and remained somewhat protected.

Anyhow, even though it feels a bit creepy to have the thing in the shop, I'm going to tear it down for salvageable parts if any exist. I've got a running Atlas 618 as well as an new-old Atlas mill, both of which have parts crossover. I already see a countershaft assembly that isn't too far gone and there might be others. So while I don't really need another project just now, it looks like I've got one. Time to start a fresh tank of molasses....

Thanks for looking, and if anything really nifty shows up along the way I'll post the findings here.

-frank