- Joined

- Sep 3, 2012

- Messages

- 53

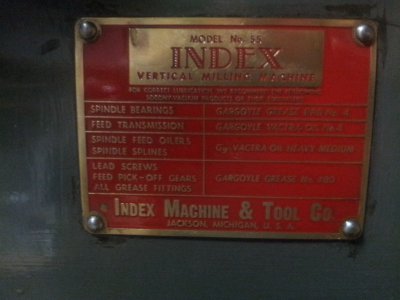

Re: Just got my Model 55

I.RonMann

I thank you for the offer on the replacement Delco motor, but I replaced the motor with a new one from Lesson, and changed the belt to a link belt, sanded and painted the pulley cover ( as well as 1/2 the mill ), my next step is to get a VFD to replace the static converter, have been working on my lathe, or more like tweaking it ( change to a QCTP from turret post ), truing the backplate to minimize chuck run out. Got all my mill bits in one rolling cabinet, and it's heavy, and made 1 tool for the mill ( something to hold my dial indicator for tramming the head ), and and going to make a pin wrench to adjust the preload on the spindle bearing. I also spot clean the mill here and there as I find time ( among my many other projects outside of hobby machining that I do ).

I.RonMann

I thank you for the offer on the replacement Delco motor, but I replaced the motor with a new one from Lesson, and changed the belt to a link belt, sanded and painted the pulley cover ( as well as 1/2 the mill ), my next step is to get a VFD to replace the static converter, have been working on my lathe, or more like tweaking it ( change to a QCTP from turret post ), truing the backplate to minimize chuck run out. Got all my mill bits in one rolling cabinet, and it's heavy, and made 1 tool for the mill ( something to hold my dial indicator for tramming the head ), and and going to make a pin wrench to adjust the preload on the spindle bearing. I also spot clean the mill here and there as I find time ( among my many other projects outside of hobby machining that I do ).

lol Going to work on the head some more this weekend, scrub all of it down, and bring her all together for the measurements. I am going to hold off on the new paint for right now,

lol Going to work on the head some more this weekend, scrub all of it down, and bring her all together for the measurements. I am going to hold off on the new paint for right now,