- Joined

- Sep 3, 2012

- Messages

- 53

Just got my Model 55

Finally. after losing out to mills on craigslist and eBay, since most of them were gone by the weekend. I happened to check the recycler for my area, not expecting to find any mill. It was my luck when I found one from an estate sale, where

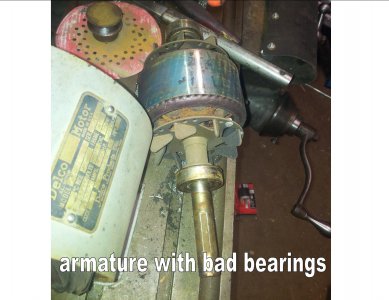

there was a a garage full of tooling, including 2 lathes ( one Logan, one Colchester Dominion ( still for sale )) drill presses, bandsaws, welders etc.. I picked up the mill and related tooling ( 3 big plastic tubs full of it ) along with a huge vise that was on the table. It runs, though I need to replace some drive belts. It has a home made static converter for the 3 phase 1 hp motor. It has what I believe is B & S #9 spindle taper, though it also came a with a Z type collet adapter and the Z type collets in a set. I hired a local mover to move it for me as I did not want to try to move it from the house where it sat due to the long driveway and the street which was on a 5% or so slope. The machine feels pretty good in terms of play, though further inspection may reveal the scope of wear on the ways / screws. Over all it is in pretty clean condition for such an old mill.

Finally. after losing out to mills on craigslist and eBay, since most of them were gone by the weekend. I happened to check the recycler for my area, not expecting to find any mill. It was my luck when I found one from an estate sale, where

there was a a garage full of tooling, including 2 lathes ( one Logan, one Colchester Dominion ( still for sale )) drill presses, bandsaws, welders etc.. I picked up the mill and related tooling ( 3 big plastic tubs full of it ) along with a huge vise that was on the table. It runs, though I need to replace some drive belts. It has a home made static converter for the 3 phase 1 hp motor. It has what I believe is B & S #9 spindle taper, though it also came a with a Z type collet adapter and the Z type collets in a set. I hired a local mover to move it for me as I did not want to try to move it from the house where it sat due to the long driveway and the street which was on a 5% or so slope. The machine feels pretty good in terms of play, though further inspection may reveal the scope of wear on the ways / screws. Over all it is in pretty clean condition for such an old mill.

Last edited: