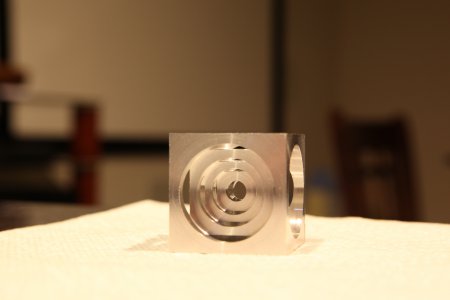

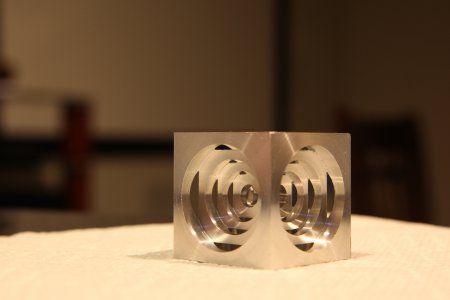

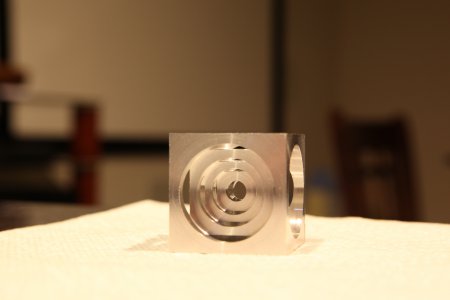

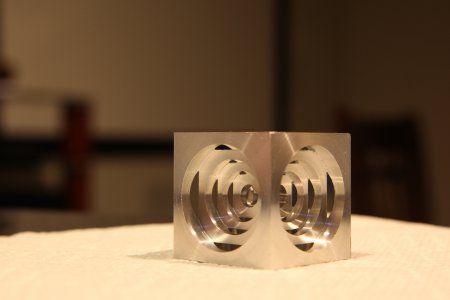

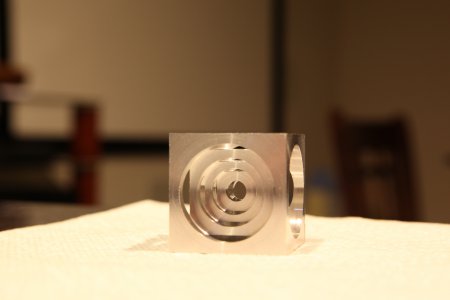

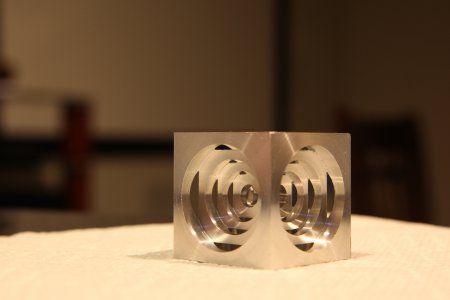

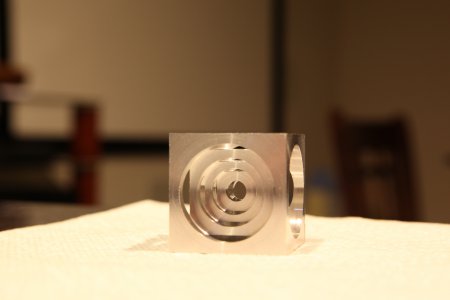

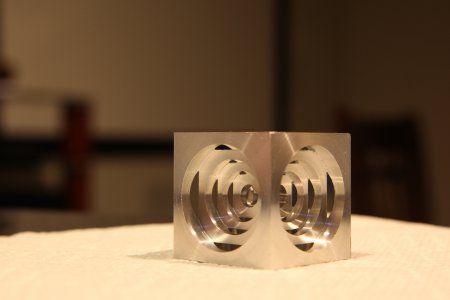

This was my first 'real' lathe project, and it was just a tremendous learning experience.

- The 123D file is here: http://www.123dapp.com/123D-3D-Model/Turners-Cube/1247843

- It basically follows a profile of a 5/16-ish hole through the middle, then measure in a .150, shoulder, drop in a .240 for the first recess, then in for the second .200 shoulder, then drop down .180 for the second recess, then in .170 on the third shoulder, then finally .150 for the final recess and shoulder.

- Sharp tools are so key for getting a good finish! I didn't touch my carbide to the grinder, I still have to learn if/how to do that, but my HSS is night and day when sharp. I learned so much about listening and feeling the chatter doing this. With that said, my next project has to be something to lock down the saddle to the bed, or I'm going to throw this 7x14 at a wall. The way the tool currently 'pulls into' the work is so frustrating.

- I see that me and my magnetic base indicator are going to be really close friends. I had NO idea I would use it so much to setup work, and I feel like half the effort was setting up work correctly.

- Starting out with bar stock, and squaring it on the lathe (no mill yet) took forever. Forever. Oh God, can't wait for the mill and fly cutter to get here next week.

- I killed a cheapo digital caliper that I was using for reloading. Time to hit up ebay for a Starret/BS/Mitu, or Enco or Shars for a 'mid-grade' caliper. Sigh. Mercifully all my other equipment survived the exercise.

- I am so happy with how it came out. I really need to think through work-holding better, because (as you may see) subsequent clamping really can mar the surface. Now a little about that, I did this in my 5" 4-jaw chuck, and used 4 square pieces of 1/8 Steel to distribute the clamping torque. In between the steel and the work, I had one small thickness of shop towel which I (wrongly) thought would prevent surface marring. Wrongo. Anyway, it gives the piece 'character'

.

- I have (easily) 30 hours in this. I'm hoping my future efforts go more quickly, or I'm going to accelerate the CNC games. Which (obviously) will make all time and effort go away

.

- Hope you like it, I sure do!