- Joined

- Oct 17, 2012

- Messages

- 126

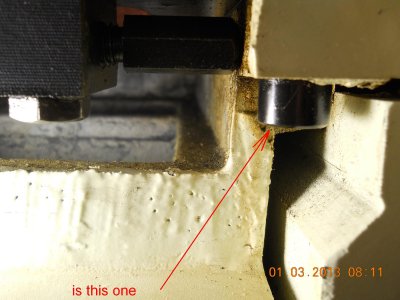

HEADSTOCK IS NOT PINNED. AS SHOWN IN POST #1. THE ADJUSTMENT SCREWS ARE PLACEBOS. I really, really need some help from someone that has done this.

Using a dial indicator at the rear of the HS, there is not movement when adjustments are turned. That is why JET avoided the issue.

Help me I've fallen and cant get up. Hee Hee

Mike

Using a dial indicator at the rear of the HS, there is not movement when adjustments are turned. That is why JET avoided the issue.

Help me I've fallen and cant get up. Hee Hee

Mike