- Joined

- Apr 23, 2011

- Messages

- 2,476

never to old to learn.............

Steve, I have never heard of,... considered,........... or even thought of, the theory of alignment behind that, but that is just so simple it stuns me,..

I am still learning now. Just going over center.............Nelson, where is the big "self head slap along with a kick up the butt" smiley?

Cheers Phil

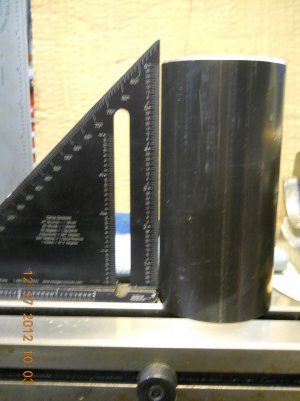

That angle will make a cone pointing in or out

Steve, I have never heard of,... considered,........... or even thought of, the theory of alignment behind that, but that is just so simple it stuns me,..

I am still learning now. Just going over center.............Nelson, where is the big "self head slap along with a kick up the butt" smiley?

Cheers Phil