- Joined

- Jul 11, 2023

- Messages

- 17

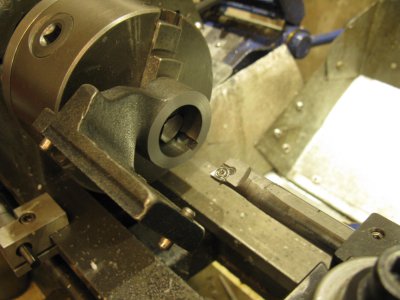

This casting has a lot of wear on the casting where the worm gear sits on a 10K. I guess I could mill it down and then shim the gear but I not sure its worth the effort. I see some on eBay for the apron casting but its hard to tell from pictures if they have any wear issues. The wear on this casting is bad on both ends of the bore.

Any ideas on how to proceed with this is appreciated.

Any ideas on how to proceed with this is appreciated.