- Joined

- May 12, 2019

- Messages

- 15

Thanks. I'm familiar with those. I was just surprised that they were so low. while high current through a switch isn't ideal, that cutoff for such a small unit would be most direct, less parts to fail, and faster imo. seems like i fall under its limits so ill probably give it a whirl at some point.For the e-stop, you can use those switches if you use them with a relay, sometimes called a "contactor". You have the e-stop switch run the coil, the contacts go to the main switch. You can also use them with the motor controller like a VFD if your machine has one.

Figured as much. Not overly concerned. Just poking to see if anyone had clever solutions to share.Chips flying, yeah, happens. You can make various shields to try to keep them in place, or just accept it. I find the mill is far more messy, but the lathe can sure fling stuff once in a while.

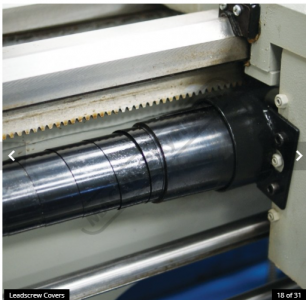

that chart i posted is all that exists in the documentation. Its not surprising. The Grizzly unit is just the rebranded China unit with slightly better customer service and maybe a bit better manual. I'm just surprised they didnt put in the chart all the speeds or ratios. they only give values for those lever positions and change gears. glad to hear i'm not taking crazy pills and i can make them slower than documented with the change gears.The feed rates, and threading, are set with change gears. You can likely find a gear set with a slower feed to get better finish. That chart shows 4.7 thous/rev as the slowest rate with those gears. It's not uncommon for me to run 1 thou/rev for a finish pass. There is likely a chart somewhere in the documentation that shows the recommended setups. And there have been a few people that have made spreadsheets and such to calculate them. Getting everything to fit is another issue as well.

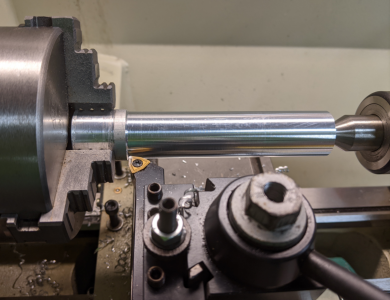

yeah i was winging it. I'll try to looks some things up for correct feeds/speeds. was just excited to make some chips. I was just leveraging what came with the lathe. I'm working on getting my hands on some HSS blanks. i just like the no fuss buy and replace sharp insert nature of indexable carbides. Do they make HSS inserts?For finish, carbide on small machines can be iffy that way. You can do better if you use the right feeds and speeds, but HSS will likely still outdo it. If you want to stick to inserts, try some polished inserts usually made for aluminum. They tend to be sharper and for the lighter loads we use at home, they hold up well in steel as well. And get some known material that is known to finish well. Starting with unknown material just complicates things. Even just 6061 aluminum is a good place to start. 1018 steel is not. I've had good luck with 12L14 and 303 stainless as well.

As far as materials... I gathered up some scraps I've run across over the years and was giving it a whirl. I wager a lot of my work will be on scraps so i have to figure out eventually how to adjust on the fly. I have to find a place to get some stock. https://www.onlinemetals.com/ seems reasonable. I used to live near Fazzio's in South Jersey before their big reno. they were great because at the time you could walk to the stock warehouse and pickup cutoffs for fractions of the price. They also sold bolts by weight and had this section that was just all old odd random equipment and parts i guess people turn in for scrap that you could rummage through. Not sure what its like now. They were all more than adequate for my needs as a student at the time. I have to see if there is a place by me now that can do that. One of these places is nearby https://www.metalsupermarkets.com/ but their online pricing is significantly higher so ill have to give them a call i guess and to see what's up.

ooooo thanks for the info. Yeah i was looking for a good chart about all the different shapes, tips, angles etc of cutters and what they were optimal for. I'm gonna work on getting some HSS but I've got all this now which can't be useless so i'd like to leverage it. I will say the next size down from 1/2 probably would have been optimal for these holders but they fit. I almost got an AXA but it would have put these cutters over the center line of the lathe from my math and I was told the added rigidity would exceed the rest of what my mill could leverage anyways. soooo ¯\_(ツ)_/¯I personally love the CCGX or CCGT inserts. Specifically the CCGX32.50 is my weapon of choice for a lot of things.

Shars sells the asian brand ZCC for a lot of their inserts. They seem pretty high quality, much much better than Banggood or AliExpress inserts, but they cost proportionately more.

These inserts are pressed and then ground to a sharp edge (compared to pressed only for most steel cutting inserts). This dramatically reduces cutting forces at the expense of a weaker edge. I've found these to have near infinite life in aluminum and a pretty good life in steel and stainless. In fact these would be the only thing I'd use in stainless.

The last digit in the designation (CCGX32.50) indicates the corner radius. 0 = sharp, 1 = medium, 2 = large. The larger the radius, the faster you can feed for a desired surface finish. This however increases cutting forces and messes with dimensional accuracy. I prefer the sharp (0) corner since cutting forces are minimized and I can get within 2-3 tenths of my desired diameter without too much hassle. I'm also not in a rush and don't mind a longer machining time to get a nice finish.

The other benefit is the minimum depth of cut. With all tools, the sharpness of the edge indicates the minimum depth of cut at which the tool will no longer cut material and instead rub over the surface. With many steel focused inserts, this could be as large as 0.015" giving you very little flexibility to dial in a finishing pass (hence some people's preference for HSS). With these inserts, I've done depth of cuts in the 0.0005" range and still had it form a real chip. Once you get dust or crumbles, then you are no longer cutting.

Interesting. I'll have to find a chart that shows what all my chips should be looking like.

Last edited: