absolutely. on the plywood mock up there is a steel square clamped underneath right now to keep it flat and square.That does seem good. In the metal one, I’d put a gusset on it to stiffen the horizontal.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

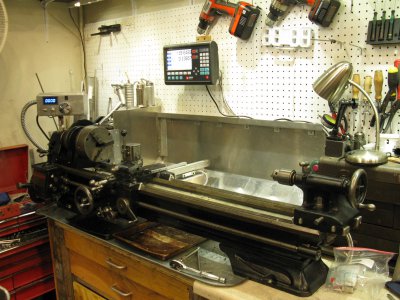

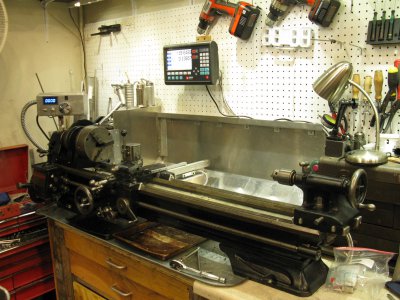

Installing Igaging Absolute DRO's on 1953 SB 9A

- Thread starter yota

- Start date

- Joined

- Sep 28, 2013

- Messages

- 4,319

here's mine (glass scales, but similar deal)

with the lathe the right way round

on my Atlas 618 I was able to get my iGaging scale partially within the carriage itself with a small amount of milling. Having it only supported at one end made it a little jittery, hence the changes I implemented on the SB9

with the lathe the right way round

on my Atlas 618 I was able to get my iGaging scale partially within the carriage itself with a small amount of milling. Having it only supported at one end made it a little jittery, hence the changes I implemented on the SB9

Last edited:

- Joined

- Sep 28, 2013

- Messages

- 4,319

wasn't suggesting that your mock ups were supported only on one end, only that on my Atlas it was and that wasn't ideal, hence I made changes to my own lathe.

This "outrigger" mount is obviously a common solution but I'm having a hard time visualizing why the read head can't be attached to the cross slide and the beam mounted to the carriage. That's how I did my x-axis DRO on my mini-lathe. Is it because the cross slide has a large range of travel?

guessing you didn't read my 1st post in this thread.This "outrigger" mount is obviously a common solution but I'm having a hard time visualizing why the read head can't be attached to the cross slide and the beam mounted to the carriage. That's how I did my x-axis DRO on my mini-lathe. Is it because the cross slide has a large range of travel?

" note that this unit would fit atop the carriage next to the cross slide but A. it would block access to the gib screws, B. it would make access to the compound lock screws more of a pain than they already are

- Joined

- Nov 21, 2021

- Messages

- 36

Hi Yota,

That's a good looking DRO setup and your SB9A looks in great condition. I have a Boxford 9A which is s clone of your SB 9A. Would you mind asking a question or two about the SB9A? Tony Griffith on 'Lathes' says the clones are mechanically identical. I want to know if this is true regarding the gear train. On the imperial Boxford when you are using the gearbox the 'standard' gear train has a 20 tooth stud gear and 56 tooth leadscrew gear (LSG). The metric version uses 50T stud and 45T LSG. Do the South Bend lathes use the same setup? Thanks!

That's a good looking DRO setup and your SB9A looks in great condition. I have a Boxford 9A which is s clone of your SB 9A. Would you mind asking a question or two about the SB9A? Tony Griffith on 'Lathes' says the clones are mechanically identical. I want to know if this is true regarding the gear train. On the imperial Boxford when you are using the gearbox the 'standard' gear train has a 20 tooth stud gear and 56 tooth leadscrew gear (LSG). The metric version uses 50T stud and 45T LSG. Do the South Bend lathes use the same setup? Thanks!

hello Evan. and thanks. I finally got my hands on some aluminum stock and am putting the final touches on the outrigger mount. as to the gears you mention, I can check mine tomorrow and tell you what mine has. I would have no idea what gears a South Bend metric model would have. first, I have to figure out which is the stud gear.