Thanks Will

It's 1943 or so old British made Sphere back lathe similar to the Atlas 10 F of the day , it has a ten & a half inch throw , with a 5 " chuck , I have the original 3 & 4 jaw chucks & the original face plate plus the original lantern tool post c/w cup ring and wedge . It also had a MYFORD over center fulcrum tool clamp that could handle 1" square tooling and a more modern MYFORD machined block four face tool holder that took up to 1/2" square shanks

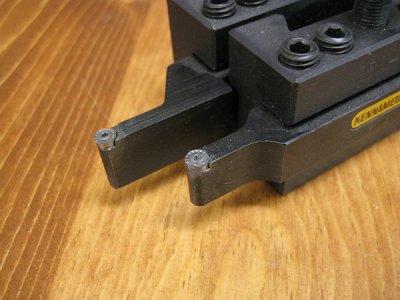

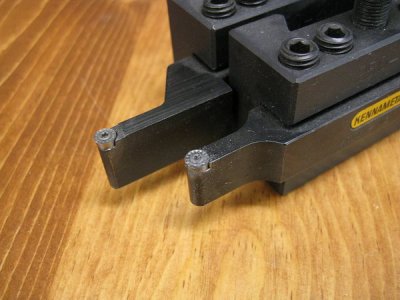

It wasn't as good as I think it can be with these arrangements so I have lashed out and purchased a QCTP . This qctp can handle all the various high carbon , HSS square & square tool steel that came with the lathe when I purchased it .

To give a bit of standardization I purchased a boxed set of nine pf 16 mm shanked indexed tools , The QCTP has 2 x round bar , one 5/8 x 3/321 parting , one knurler complete & four more 16 mm square straight shank holders .

One thing I have done was take up as much play in the slides by adjusting the gibs & had to file the top of the compound slide down flat as some Pratt had used a standard high tensile bolt to fit an ancient Myford fulcrum arm type tool post , it has obviously been rotating in the slot as the slot has a definite cone " chavelled out" mid way along consequently starting to pull the top lips of the "T" slot upwards by about 15 thou.

I gave it a bit of a test run for a week or so and have found it totally different to the older cutting tools and older tool posts.

So any tips to think about would be most gratefully read and worked with .

The QCTP is a piston type with two faces at 90 degrees to each other supposed to be a best fit for a 10 to 12 throw lathe. the tool holders accept 5/8 " ( 16 mm ) square tools ( the next size down would have only been able to take 1/2 square tooling .

I didn't fancy the smaller size tooling for an 8 to 10 inch throw or the available QCP for that range of lathe . for after consulting the oracles on the site I gather that is would not have been so solid when sat high up on the compound slide . i also had a lot of 5/* tooling for HSS , brazed tungsten tips and some ancient hand forged high carbon steel tooling.

Re .. Darts :-

I did meet a guy about 20 years ago who swore that he had machined & ground up some used depleted uranium rounds recovered from a gunnery range where he & the " warthogs were playing ".

I don't know if he was talking through his butt , however the barrels of the darts were exceedingly heavy , like thin knitting needles & flew to the board like guided missiles .