- Joined

- Sep 8, 2019

- Messages

- 4,392

I just bought a lathe chuck that weighs 165 lbs. I am soliciting ideas on how to store this and another chuck that weighs 140 lbs. I also don’t have a place to put my 5C collet chuck on D1-6 backplate.

I use a tool post crane to switch between chucks. I would like a *cart* to wheel over to the lathe when I do this.

The tool post crane chain *does* reach down to the floor if I end up choosing a very low cart (like a furniture dolly).

I am currently using a Miller TIG Runner (welding) cart to store the 140 lb chuck, but this cart really is too narrow for a 12-1/2” chuck. It looks like a tipping risk!

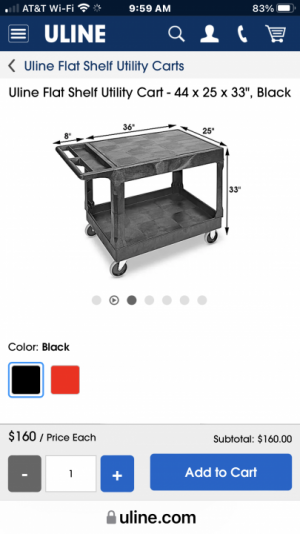

I am considering either a huge rolling cart, or a hydraulic cart.

I’m not sure what benefit I would get from the hydraulic cart other than being able to lower it down when not in use, this in order to lower the center of gravity so that it doesn’t tip over.

I have needed a hydraulic cart once in the past, for the purpose of removing my benchtop mill off of it’s stand. I still need to repaint and re-level this mill stand.

A huge cart would almost certainly be in the way. A benefit from this would be a lot of much needed storage on the bottom.

I wish I had time to build a cart to my specifications, but I have projects that I’ve been working on for 3 years that are stalled due to long hours at work.

After posting this, I am starting to lean toward the hydraulic cart so that I can use it for that other (milling machine stand) project.

I use a tool post crane to switch between chucks. I would like a *cart* to wheel over to the lathe when I do this.

The tool post crane chain *does* reach down to the floor if I end up choosing a very low cart (like a furniture dolly).

I am currently using a Miller TIG Runner (welding) cart to store the 140 lb chuck, but this cart really is too narrow for a 12-1/2” chuck. It looks like a tipping risk!

I am considering either a huge rolling cart, or a hydraulic cart.

I’m not sure what benefit I would get from the hydraulic cart other than being able to lower it down when not in use, this in order to lower the center of gravity so that it doesn’t tip over.

I have needed a hydraulic cart once in the past, for the purpose of removing my benchtop mill off of it’s stand. I still need to repaint and re-level this mill stand.

A huge cart would almost certainly be in the way. A benefit from this would be a lot of much needed storage on the bottom.

I wish I had time to build a cart to my specifications, but I have projects that I’ve been working on for 3 years that are stalled due to long hours at work.

After posting this, I am starting to lean toward the hydraulic cart so that I can use it for that other (milling machine stand) project.