- Joined

- Jun 20, 2022

- Messages

- 206

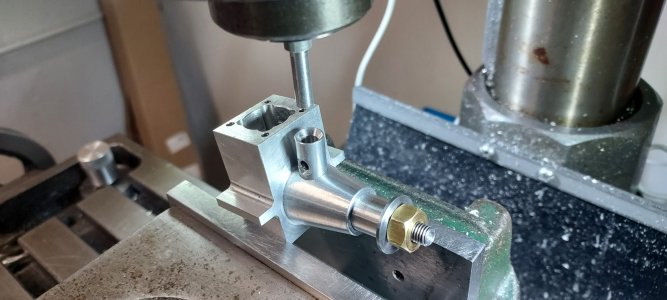

Thanks for the continued support guys. I was able to get it assembled and decided it was too tight. It wouldn't "flip" over by hand just drag (in other words it could be turned over by hand, but would not free wheel really for the bottom half of the stroke). I pulled it back apart and lapped the piston for about 10 seconds. This felt much better. It now could be flipped, but compression still felt OK.

I mixed some fuel with the JD80% ether, and put it on the test stand. I have been able to get a couple short "brapps" and a couple wisps of smoke from the exhaust. So this is a major improvement over last time. Hopefully with some fine tuning of compression and fuel I can get it to actually fire up for more than 2 or 3 cycles.

I mixed some fuel with the JD80% ether, and put it on the test stand. I have been able to get a couple short "brapps" and a couple wisps of smoke from the exhaust. So this is a major improvement over last time. Hopefully with some fine tuning of compression and fuel I can get it to actually fire up for more than 2 or 3 cycles.