- Joined

- Jun 20, 2022

- Messages

- 235

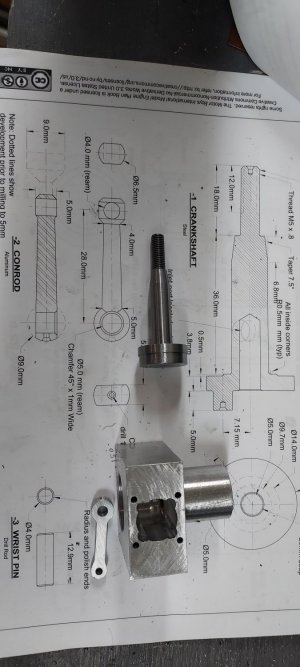

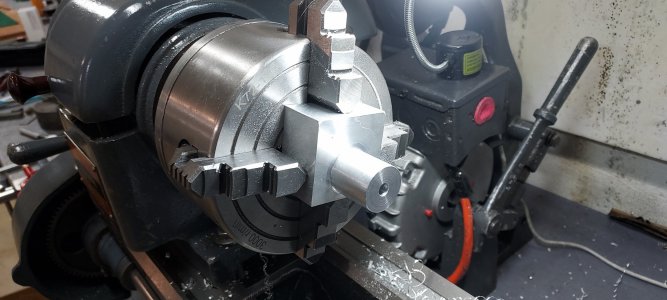

Found free plans and some detailed instructions for an Owen Mate 2cc online. I have RC planes so if this works it might go in a plane.

Here's where I am.....

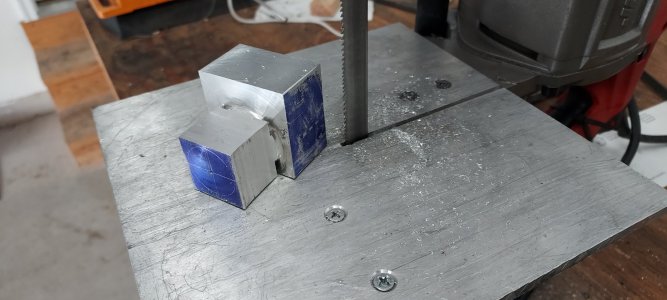

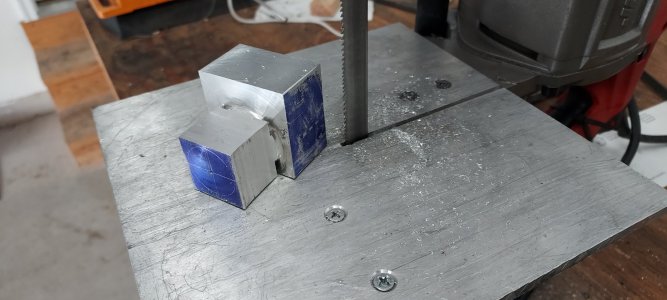

No casting available, rough cut block from 2"x2" AL stock

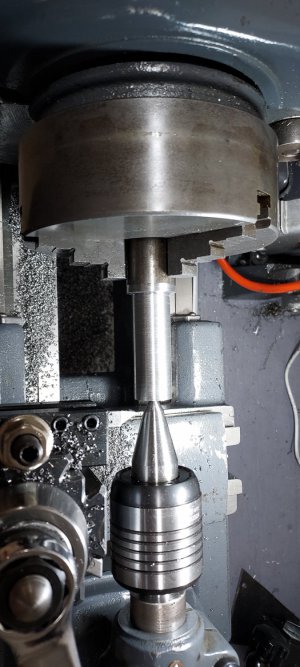

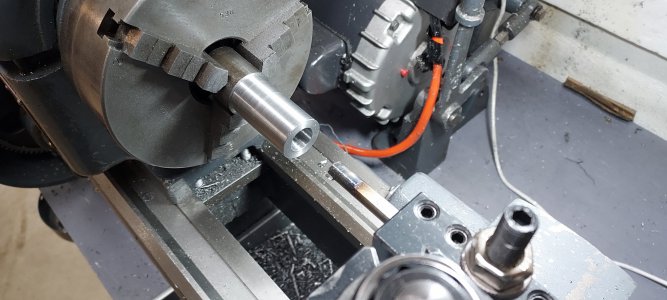

Block was first squared on the milling machine then nose turned to 24mm and started at 5/16"......

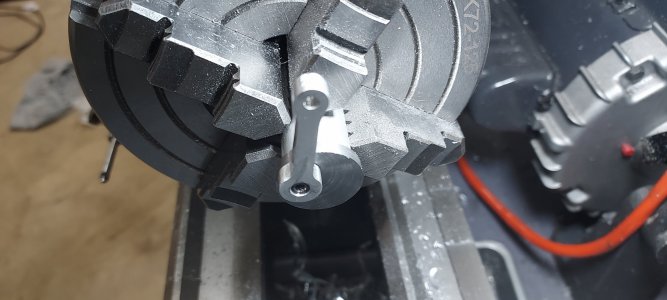

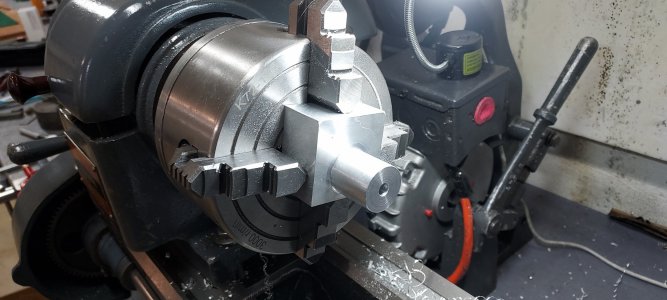

Backplate was custom threaded at .960" x 24tpi because my lathe won't do the specified metric threads.....

Started too small on the mating bore for the backplate, but managed to get it threaded to fit eventually.

Backplate fits!

This was supposed to be a "winter project" but I got excited to start!

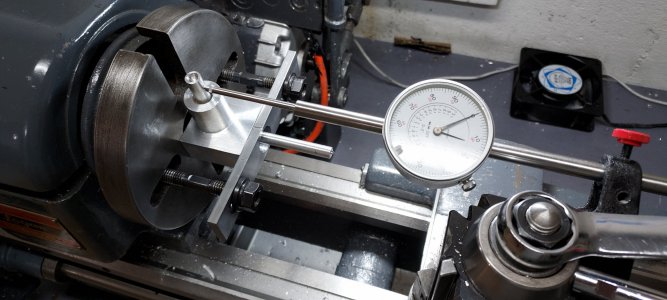

I have a bronze bearing in the nose and a ground 3/8" rod to use as a datum line to measure off of. Next up is drilling the head hold down holes, transfer passages, and cylinder boring the block. Will brush up on TouchDRO bolt circle then proceed.

Here's where I am.....

No casting available, rough cut block from 2"x2" AL stock

Block was first squared on the milling machine then nose turned to 24mm and started at 5/16"......

Backplate was custom threaded at .960" x 24tpi because my lathe won't do the specified metric threads.....

Started too small on the mating bore for the backplate, but managed to get it threaded to fit eventually.

Backplate fits!

This was supposed to be a "winter project" but I got excited to start!

I have a bronze bearing in the nose and a ground 3/8" rod to use as a datum line to measure off of. Next up is drilling the head hold down holes, transfer passages, and cylinder boring the block. Will brush up on TouchDRO bolt circle then proceed.

Last edited: