- Joined

- Jun 17, 2012

- Messages

- 2,220

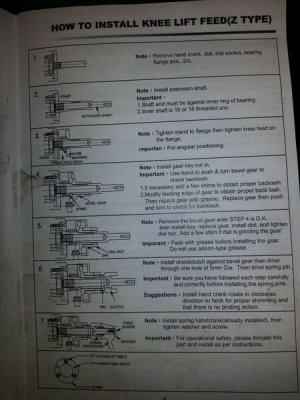

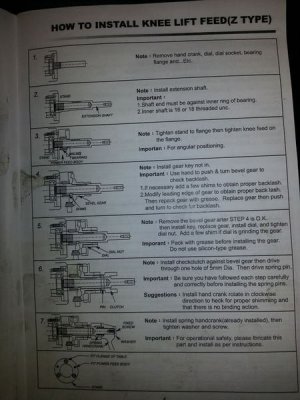

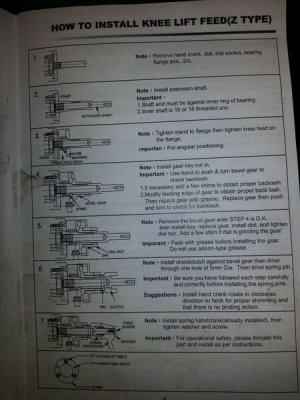

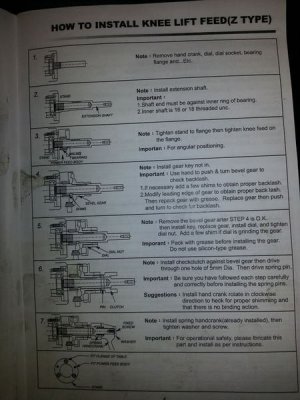

I just got a powerfeed from Enco for my z axis. I nthe instructions it sais to remove the dial, dial socket and bearing flange. I'm stuck at the dial socket. I pulled the whole z crank shaft out of the knee, that was easy. The dial socket which is to the right in the photo seems to be press fit, but before I ruin something I gotta know for sure. This part and the bearing flange need to come out so that I can install the powerfeed. Any help would be greatly appreciated.

Here's the instructions that came with it. They're not very specific as to the dismantling of the existing machine.

Thanks

Marcel

Here's the instructions that came with it. They're not very specific as to the dismantling of the existing machine.

Thanks

Marcel