- Joined

- Sep 18, 2014

- Messages

- 254

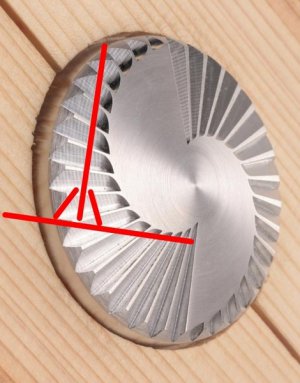

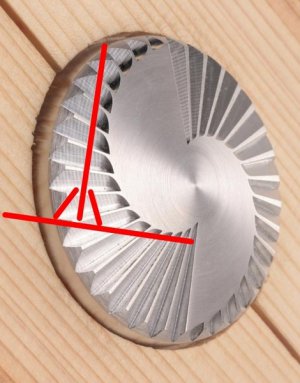

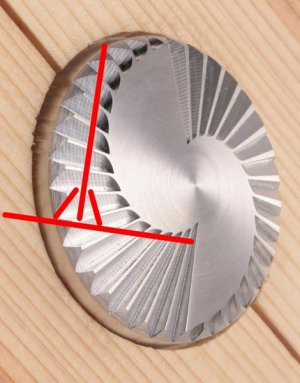

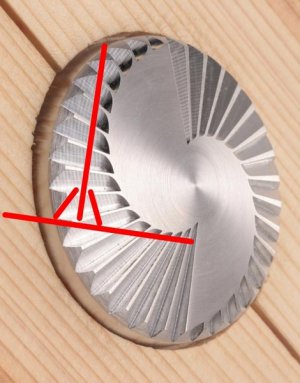

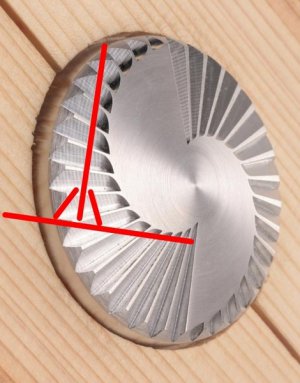

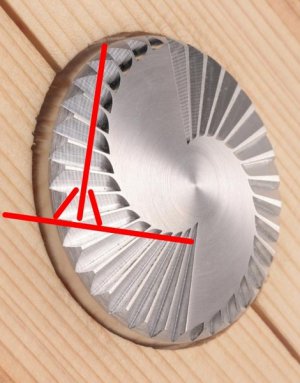

It's an optical illusion from that stand point. I agree with the dove tail cutter on a vertical rotary table.

Steve Shannon

Steve Shannon

Well, let's have a mill-off......see who can come closest to duplicating that profile.