- Joined

- May 20, 2017

- Messages

- 162

Thanks, Shawn.

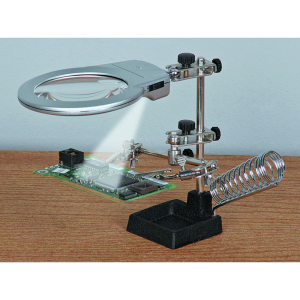

One thing this project made clear. I need to get a good desk magnifying lamp, or maybe a head type. I had a very hard time seeing what I was doing.

My eyes are not so great either. I have a few of those Luxo desk lights with the center magnifier and circular fluorescent lamp. The Luxo's seem sufficient for me in handling small parts and small soldering. If you get a head type - go for the visor unit in lieu of the magnifying glasses - unless you opt for the expensive top-shelf glasses like what surgeon would wear and made for your eye corrective prescription, etc.