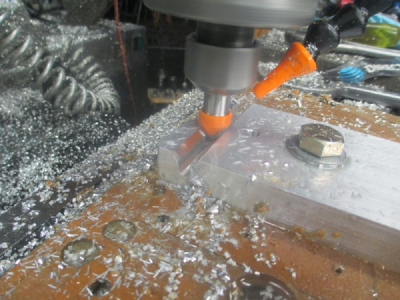

Hey guys I have a small grizzly g0704 mill that i would like to make a lathe crotch for my little mini lathe..

what I have done is turn and face bore and tap for the mt2 arbor .....now how can I do this to get it exactly center?

my thought is blue the face scribe center line and use the end of the endmill to line it up...I will have to tilt the mill head because I have no good means to hold this round part at 45 deg..I want to cut a V in

suggestions comment etc..

I really dont have the money to buy a proper horizontal V cutter...

Thanks

Lawrence

what I have done is turn and face bore and tap for the mt2 arbor .....now how can I do this to get it exactly center?

my thought is blue the face scribe center line and use the end of the endmill to line it up...I will have to tilt the mill head because I have no good means to hold this round part at 45 deg..I want to cut a V in

suggestions comment etc..

I really dont have the money to buy a proper horizontal V cutter...

Thanks

Lawrence