- Joined

- Dec 18, 2019

- Messages

- 6,464

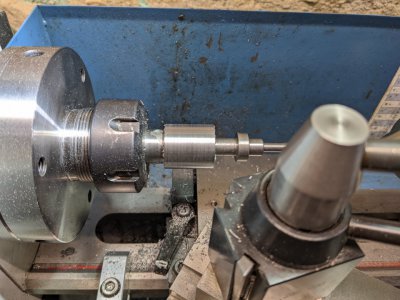

Beginning to see why one would go with multiple pieces. (Dawn rises over Marblehead.) Dang, that's a skinny long piece so far. I turned the 1" down to nearly 1/4" for 52mm. Yes, I do have a live center at the end. Thank goodness. Got a little bit more to go on the diameter. Final DOC's will be small, since the piece seems like it will deflect in a breeze.

This is what I have so far. Threading went much easier than expected. All cuts under 0.005". Actually cut it almost perfectly. Spun a die on it and it barely cut anything. Used the AXA-8. Cut beautifully.

This is what I have so far. Threading went much easier than expected. All cuts under 0.005". Actually cut it almost perfectly. Spun a die on it and it barely cut anything. Used the AXA-8. Cut beautifully.