-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Horizontal mill build

- Thread starter Gadget

- Start date

- Joined

- Nov 23, 2011

- Messages

- 105

Etard,

The Gingery books are a great source of information. They have all the needed information to build the machines and the detail is great. There is one small error in the mill book or at least the one I have. I bought the whole series back around 1985 or so. As I recall the error was in the dimensions of the spindle bearing cap or slide. Once you are aware of the error you can easily adjust the pattern build the right way. In all the books I have from Gingery, that's the only mistake I've found.

Years ago I built the lathe. That worked quite well and I had a lot of fun with it. I eventually sold it after buying a bigger lathe.

My suggestion is start with one of the foundry furnace books, you'll need a way to cast your patterns. The book progression starts with the lathe, then the shaper, and finally the mill. You use the machine you just built to machine the parts for the next machine. I skipped the shaper but will go back and build it simply because it looks like a fun machine to build and use.

Dan

The Gingery books are a great source of information. They have all the needed information to build the machines and the detail is great. There is one small error in the mill book or at least the one I have. I bought the whole series back around 1985 or so. As I recall the error was in the dimensions of the spindle bearing cap or slide. Once you are aware of the error you can easily adjust the pattern build the right way. In all the books I have from Gingery, that's the only mistake I've found.

Years ago I built the lathe. That worked quite well and I had a lot of fun with it. I eventually sold it after buying a bigger lathe.

My suggestion is start with one of the foundry furnace books, you'll need a way to cast your patterns. The book progression starts with the lathe, then the shaper, and finally the mill. You use the machine you just built to machine the parts for the next machine. I skipped the shaper but will go back and build it simply because it looks like a fun machine to build and use.

Dan

- Joined

- Sep 22, 2010

- Messages

- 7,223

Wow...that is some project. Makes a great article too for the home (articles) page: http://www.hobby-machinist.com/content.php?186-Horizontal-mill-build

Nelson

Nelson

- Joined

- Nov 23, 2011

- Messages

- 105

Horizontal mill build bed casting

Here's a short video of the pouring of the mill bed casting. The burner in this video is propane, I've since converted it to waste motor oil.

[video=youtube;hqXfmLxRqCw]http://www.youtube.com/watch?v=hqXfmLxRqCw[/video]

Here's a short video of the pouring of the mill bed casting. The burner in this video is propane, I've since converted it to waste motor oil.

[video=youtube;hqXfmLxRqCw]http://www.youtube.com/watch?v=hqXfmLxRqCw[/video]

- Joined

- Dec 15, 2011

- Messages

- 66

yep, one of these days I'm gonna be doing pourings like that...

yours look great !

any pointers?

yours look great !

any pointers?

- Joined

- Nov 23, 2011

- Messages

- 105

yep, one of these days I'm gonna be doing pourings like that...

yours look great !

any pointers?

Pointers for the mill? Or for the foundry? Not sure which one you are referring to .

- Joined

- Nov 23, 2011

- Messages

- 105

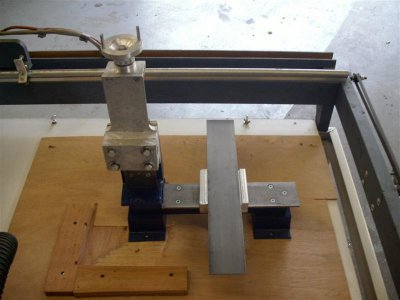

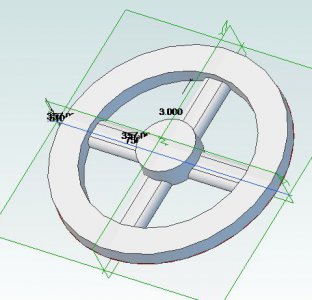

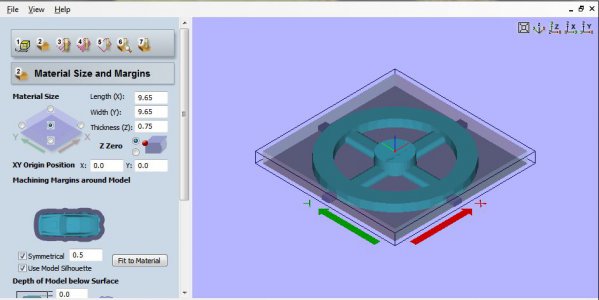

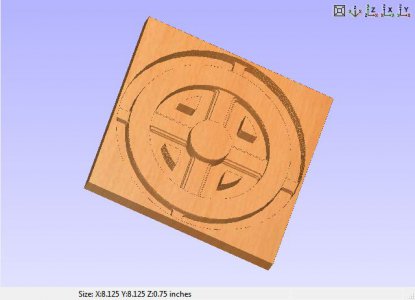

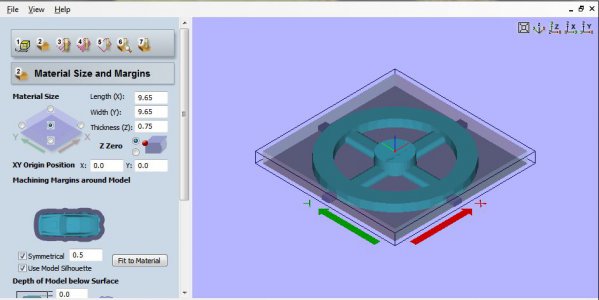

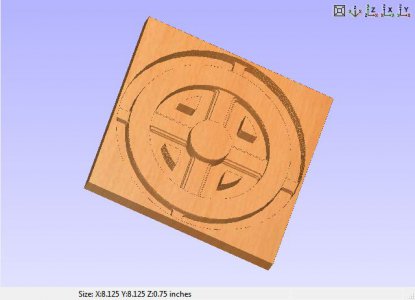

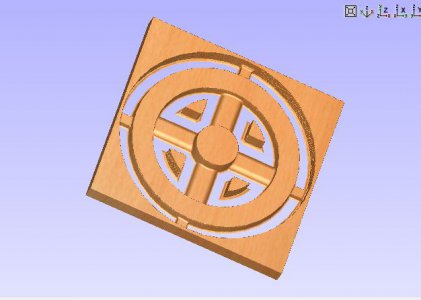

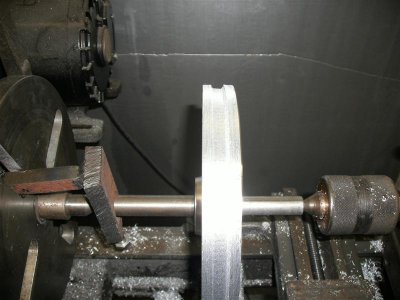

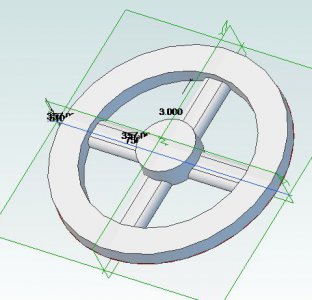

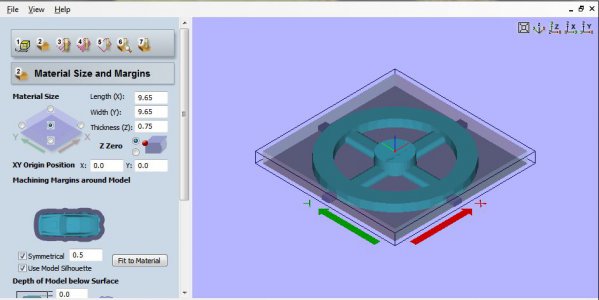

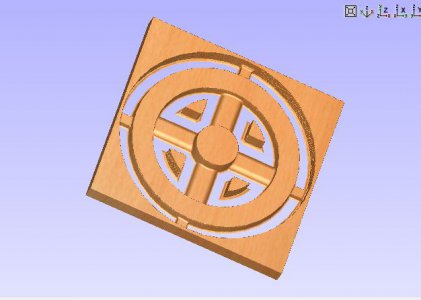

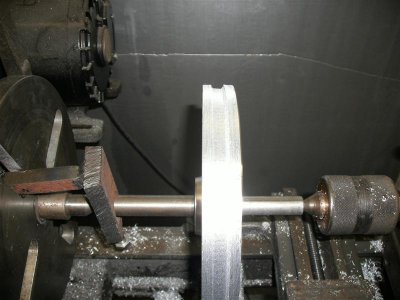

Horizontal mill build update

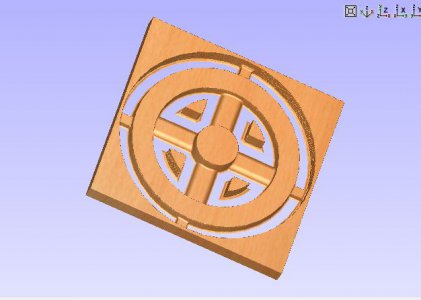

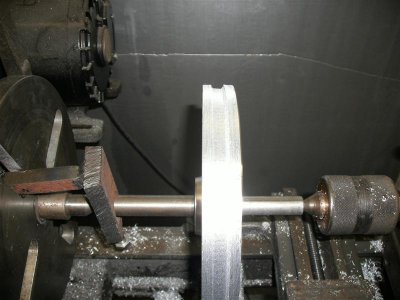

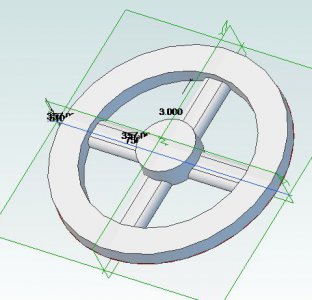

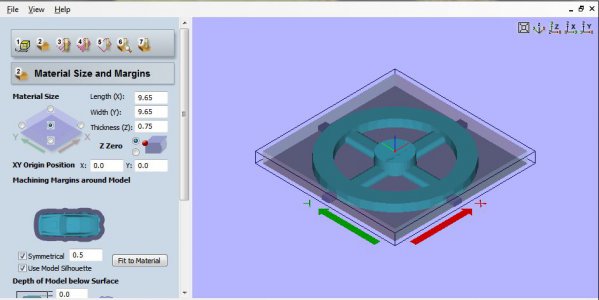

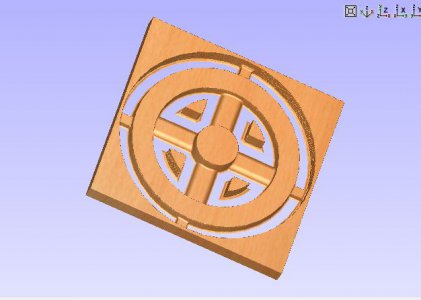

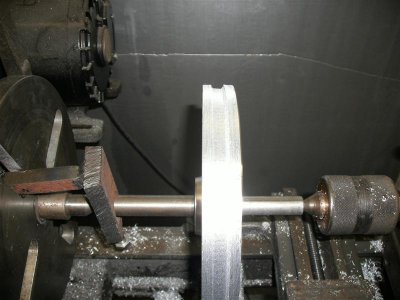

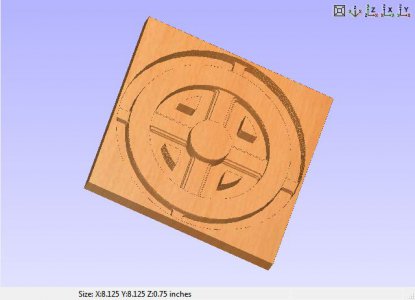

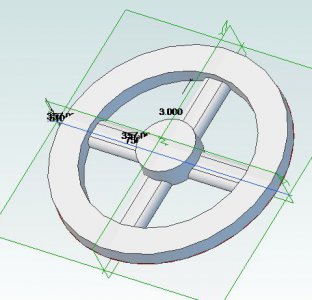

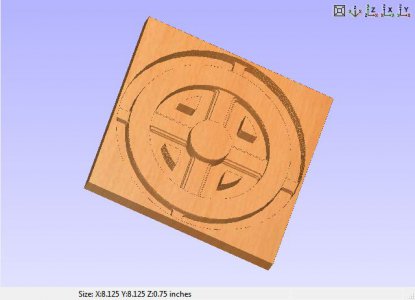

I've been moving ahead but slowly on the mill since the last post. I needed a couple of pulleys for the transmission and rather than buy them I decided to make my own. I designed them in Alibre Design and created the cut path for patterns in Vectric's Cut 3D. The next step was to cut the patterns out of MDF on my CNC router. I cast them using aluminum and finished them on the lathe. Here are some photos of that process. I have the machine under power using the temporary boring bar to bore out the spindle bore. I'll take some videos of this today and post them later.

CAD drawing

CAD drawing

Cut 3D creating machine path

Cut 3D creating machine path

Cut simulations for rough and final cut in Cut3D

Pattern ready for casting

Pattern ready for casting

Casting and machining.

I've been moving ahead but slowly on the mill since the last post. I needed a couple of pulleys for the transmission and rather than buy them I decided to make my own. I designed them in Alibre Design and created the cut path for patterns in Vectric's Cut 3D. The next step was to cut the patterns out of MDF on my CNC router. I cast them using aluminum and finished them on the lathe. Here are some photos of that process. I have the machine under power using the temporary boring bar to bore out the spindle bore. I'll take some videos of this today and post them later.

CAD drawing

CAD drawing Cut 3D creating machine path

Cut 3D creating machine pathCut simulations for rough and final cut in Cut3D

Pattern ready for casting

Pattern ready for castingCasting and machining.

- Joined

- Dec 15, 2011

- Messages

- 66

I'd be referring to your castings...

those down at the start of the thread look pretty large and 'spread out'--

How do you keep the metal from cooling in all those passages before it fills the mold up?

:thinking:

those down at the start of the thread look pretty large and 'spread out'--

How do you keep the metal from cooling in all those passages before it fills the mold up?

:thinking: