- Joined

- Apr 23, 2018

- Messages

- 6,541

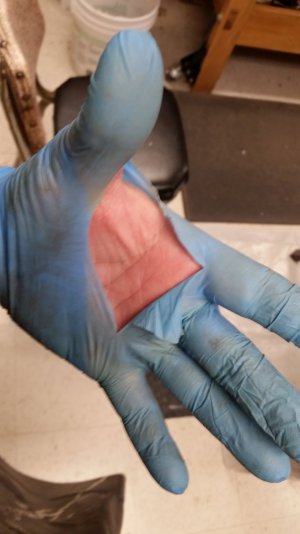

The fingertips are the thickest part of the glove, and the wrist is the thinnest. Gloves should be rated for thickness at the palm.

You also get what you pay for, but as far as gloves go, COVID blew that rule apart.

I tried their heavy black 9 mil gloves. No powder, and I can barely get XL over my hands if there's any humidity in the air. Chemical resistance is good and they are tough against stretch tears, but if you get a pinch or puncture they split open as easily as a 3 mil glove. The 7 mil gloves from Lowe's with the lizard texture are 10x better overall for every other reason. At only $2-3 a box price difference, I'll be sticking with them from now on.

You also get what you pay for, but as far as gloves go, COVID blew that rule apart.

I tried their heavy black 9 mil gloves. No powder, and I can barely get XL over my hands if there's any humidity in the air. Chemical resistance is good and they are tough against stretch tears, but if you get a pinch or puncture they split open as easily as a 3 mil glove. The 7 mil gloves from Lowe's with the lizard texture are 10x better overall for every other reason. At only $2-3 a box price difference, I'll be sticking with them from now on.