- Joined

- Dec 10, 2023

- Messages

- 76

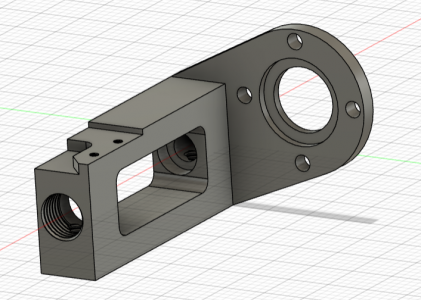

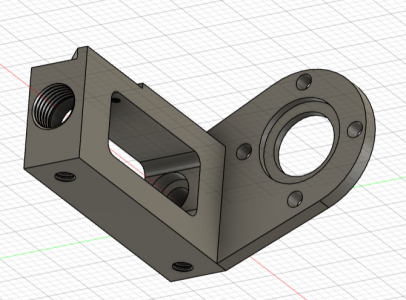

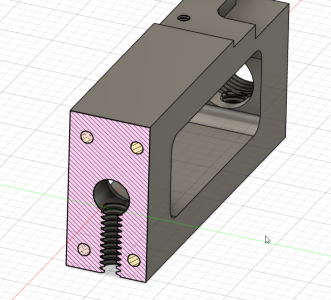

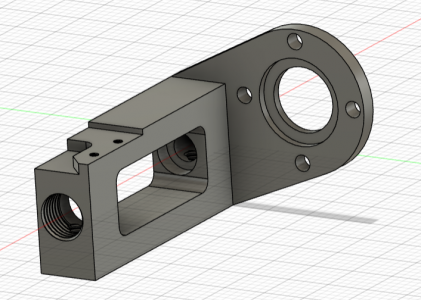

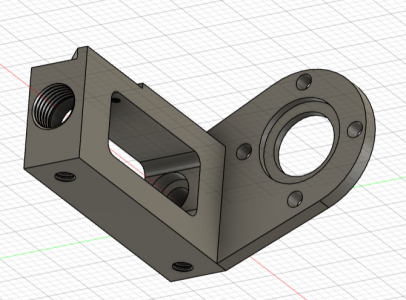

Hello, i am new to machining. My PM728VT is on order. I have a long term goal to make parts like this one that i designed. I am not sure if this kind of part is one i should start on.

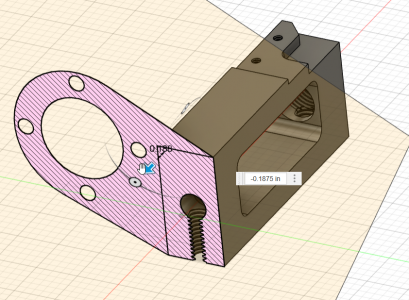

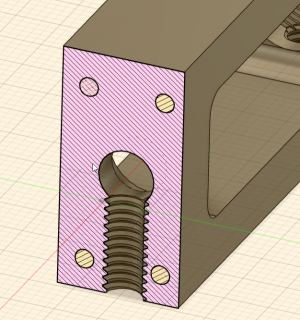

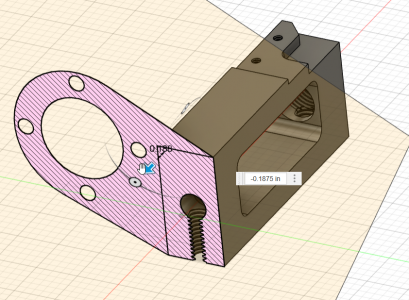

It would be a lot easier to make if i did it in two parts and bolted them together. You can see if i make it two parts i run into this 1/4 20tpi threaded hole. I cannot move the hole.

Anyone have recommendations on how to make this two piece's then attach them back together?

The final part will be 6061 aluminum. The longest dimension is 3 inches.

My idea is once i have the two piece's. I combine them into one with aluminum screws with loc tite (not sure what kind yet). Then drill and tap that 1/4" 20tpi hole after the two pieces are connected together. THis way i and drilling and tapping into all aluminum (since the fastener will be aluminum).

Any other ideas or a better way of doing this part?

Thanks!

Chad

It would be a lot easier to make if i did it in two parts and bolted them together. You can see if i make it two parts i run into this 1/4 20tpi threaded hole. I cannot move the hole.

Anyone have recommendations on how to make this two piece's then attach them back together?

The final part will be 6061 aluminum. The longest dimension is 3 inches.

My idea is once i have the two piece's. I combine them into one with aluminum screws with loc tite (not sure what kind yet). Then drill and tap that 1/4" 20tpi hole after the two pieces are connected together. THis way i and drilling and tapping into all aluminum (since the fastener will be aluminum).

Any other ideas or a better way of doing this part?

Thanks!

Chad